Sheep manure organic fertilizer production line is mainly sheep manure, straw, branches, straw production and processing of organic fertilizer. Sheep manure organic fertilizer is a new type of high quality organic fertilizer after special treatment of sheep’s incompletely digested organic matter. It is suitable for geological improvement of alkaline soil and barren land, and has a good effect on increasing crop yield.

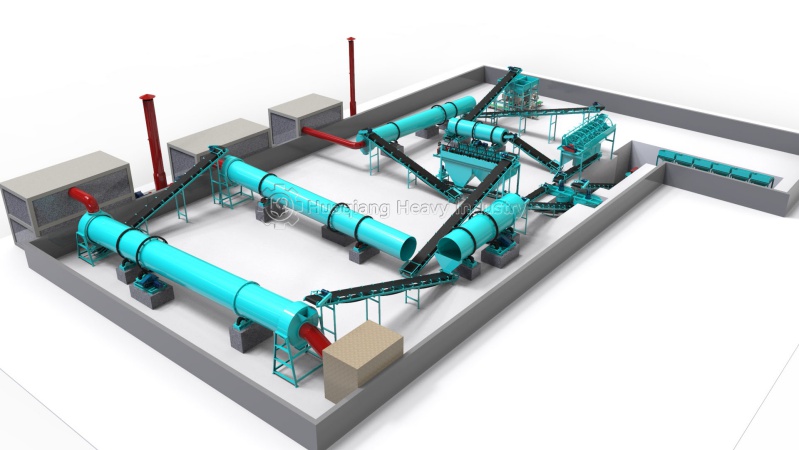

Technological process of sheep manure organic fertilizer production line

1. When sheep dung is mixed with appropriate amount of straw powder, the amount of mixing depends on the moisture content of sheep manure. Generally, 45% water content is required for fermentation, that is, the hand is squeezed into a ball, and water can be seen between fingers, but no water is dropped. Once the hand is released, it will disperse. Then, corn flour and bacteria were added. The function of corn flour was to increase sugar content for bacteria fermentation, so that multi-dimensional complex enzyme bacteria quickly took the absolute advantage.

2. Add the mixed material into the mixer for mixing. The mixing must be even and transparent without leaving raw blocks.

3. The mixed ingredients are piled into strips with a width of 1.5m-2m and a height of 0.8m-1m, which are tossed by a compost windrow turner every two days.

4. The compost was heated in 2 days, odorless in 4 days, loose in 7 days, fragrant in 9 days, and composted in 10 days (that is, the temperature on the second day of composting could reach 60 ℃ – 80 ℃, killing E.coli, insect eggs and other diseases and insect pests; on the fourth day, the odor of sheep manure was eliminated; on the seventh day, the compost became loose and dry, covered with white hyphae; on the ninth day, it gave out a flavor of koji; on the tenth day, the compost was fermented and matured).

5. After a little air drying, it can be crushed by a semi wet material crusher, granulated by an organic fertilizer granulator, dried and dehydrated by a dryer, and then screened by a screening machine. The finished organic fertilizer is ready for packaging and storage.