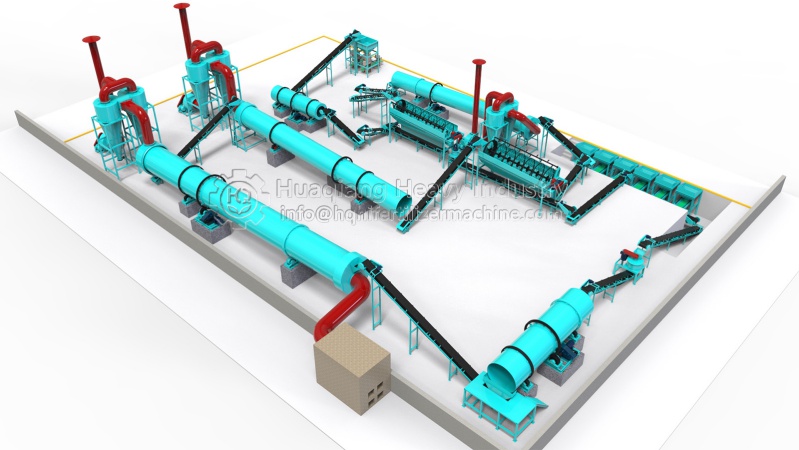

The production line of chicken manure organic fertilizer is a complete set of production equipment which uses fresh chicken manure as raw material and processes a series of organic fertilizer machine to produce natural organic chicken manure fertilizer. The production and processing of chicken manure organic fertilizer need two steps: the early fermentation and treatment part and the deep processing granulation part. The supporting equipment of chicken manure organic fertilizer needs fermentation compost windrow turner, organic fertilizer crusher, roller screen machine, horizontal mixer, organic fertilizer granulator, rotary dryer, cooler, screen machine, coating machine, packaging machine, conveyor and other equipment.

In the chicken manure organic fertilizer production line, fresh chicken manure with water content of 65% – 85% and a certain amount of auxiliary materials (dry straw, broken grass, dry chicken manure, etc.) are placed in the fermentation pile, and at the same time, the fermentation equipment (compost windrow turner) is used for full mixing; the compost windrow turner is continuously pushed to adjust the water, carbon and nitrogen ratio (C / N); the mixed fresh chicken manure is fermented for 7 days under the appropriate temperature and oxygen conditions; then it is fed into the organic manure In the fertilizer dryer, the chicken manure block is in full contact with the hot air and quickly loses the surface moisture; because the dryer is equipped with high-speed rotating crushing equipment, the chicken manure block is constantly broken and dehydrated to complete the drying process; the organic fertilizer granulator is used for granulation; the dryer evaporates the moisture in the particles; the cooler quickly reduces the particle temperature; the screening machine selects the unqualified particles Re crushing and granulation; coating of qualified particles; quantitative packaging of final organic fertilizer products.