The birth of the straw production line of Organic fertilizer can solve the problem of straw burning innocuously. This equipment can quickly and innocuously solve agricultural wastes such as straw, wheat straw, corn stalk and other crop straws that are randomly abandoned in the field and rotted and smelly or burned in the open air, completely kill diseases, pests and weeds in agricultural wastes, and quickly convert them into excellent Organic fertilizer.

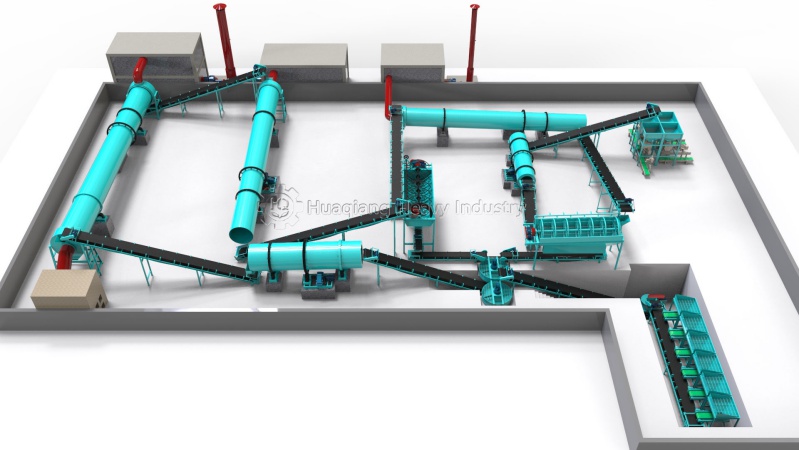

Technological process of straw Organic fertilizer production line:

1. Ingredients: Various animal excrement such as chicken manure, pig manure, cow manure, biogas residue, or raw materials that can be fermented or have fertilizer effects after treatment shall be prepared in a certain proportion (based on market demand and soil testing results in different regions).

2. Mixing of raw materials: Mix the prepared raw materials evenly to improve the overall uniformity of the fertilizer particles.

3. Raw material granulation: The evenly stirred raw material is fed into a Organic fertilizer granulator for granulation (either a drum granulator or an extrusion granulator can be used).

4. Particle drying: The particles made by the granulator are fed into the dryer to dry the moisture contained in the particles, increasing their strength and facilitating storage.

5. Particle cooling: The dried fertilizer particles have a high temperature and are prone to clumping. After cooling, they are easy to pack, store, and transport.

6. Particle grading: Grading the cooled particles, crushing and re granulating the unqualified particles, and screening out the qualified products.

7. Finished film: Coating qualified products to increase the brightness and roundness of particles.

8. Finished product packaging: Bag the coated particles, also known as finished products, and store them in a ventilated place.

The new Organic fertilizer production line uses a unique process of three in one machine to complete the whole process of low-temperature drying, cooling and screening at one time, with less equipment investment and low operating costs. The survival rate of microorganisms is>90%. Organic fertilizer production equipment is widely used in animal husbandry, large, small and medium-sized breeding plants, feed plants, and organic waste re granulation in brewing, sugar making, paper making, medicine, tobacco factories and other industries, and is the ideal equipment preferred by biological Organic fertilizer production enterprises.