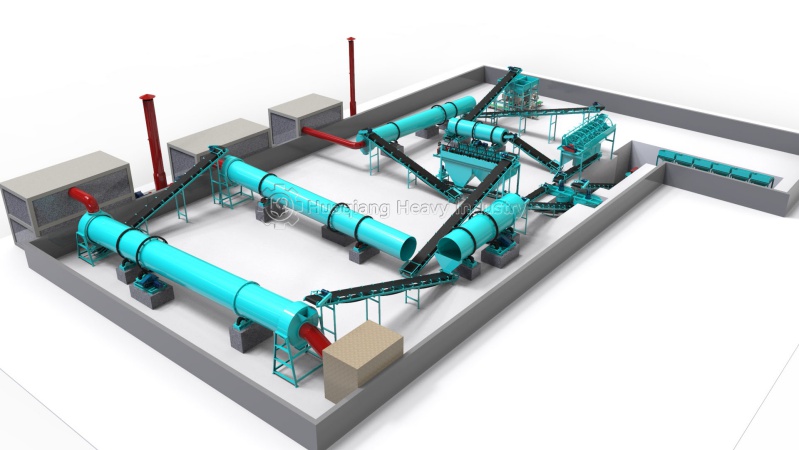

The production line for cow manure organic fertilizer involves various equipment, each with its specific function, which together form an efficient processing chain. The main equipment and their respective roles and advantages are listed below:

major equipment

1. Solid liquid separator

Function: Separate the solid and liquid parts of cow manure, which is beneficial for subsequent composting treatment.

Advantages: Improve work efficiency, reduce the cost of subsequent processing, especially necessary for cow manure with excessive humidity.

2. Fermentation tank/compost turning machine

Function: Promote the fermentation of cow manure, increase oxygen supply through flipping, accelerate organic matter decomposition, and kill pathogens.

Advantages: Improve fermentation efficiency, shorten fermentation cycle, and generate stable compost products.

Function: Crush the fermented compost material to a certain size for further processing.

Advantages: Make the material uniform and improve the granulation effect.

Function: Mix the crushed cow manure thoroughly with other organic materials or additives.

Advantages: Ensure uniform distribution of all ingredients and improve product quality.

5. Organic fertilizer granulator

Function: Press the mixed material into particles.

Advantages: Convenient storage, transportation, and application, while also improving the aesthetics and added value of fertilizers.

6. Organic fertilizer dryer&cooler

Function: Remove excess moisture from the granules after granulation, then cool and stabilize their physical properties.

Advantages: Extend the shelf life of fertilizers and prevent mold growth.

7. Organic fertilizer screening machine

Function: Remove unqualified particles to ensure the quality of the finished product.

Advantages: Improve product uniformity and meet market demand.

8. Organic fertilizer packaging machine

Function: Finally, measure and package qualified organic fertilizer particles.

Advantages: Easy to commercialize, easy to retail and logistics.

Whole line advantage

Integrated automation: Many modern production lines use PLC control to achieve automated process management, save manpower, and improve production efficiency.

Environmentally friendly: Advanced production lines will be equipped with waste gas treatment facilities, such as dust collectors, to reduce environmental pollution.

Flexible customization: Equipment combinations and parameter settings can be adjusted according to different production scales and raw material characteristics.

The entire cow manure organic fertilizer production line not only achieves effective utilization of cow manure, but also promotes the maximization of resource recovery and reuse under the green circular economy model, contributing to the sustainable development of agriculture.