Under the global trend of green agricultural transformation and solid waste resource utilization, the horizontal mixing extrusion granulation production line has become the mainstream equipment for organic fertilizer and bio-fertilizer production due to its core advantages of no drying, low energy consumption, and wide adaptability. This production line adopts a cold granulation process, eliminating the need for external heat sources and excessive binders. Through mechanical mixing and extrusion, the raw materials are directly agglomerated and shaped, perfectly matching the characteristics of high-moisture, high-viscosity organic fertilizer raw materials, effectively solving the industry pain point of poor adaptability of traditional granulation processes to organic fertilizer raw materials.

Its core adaptability lies in its broad coverage of fertilizer categories. It primarily produces pure organic fertilizer, bio-organic fertilizer, and refined organic fertilizer, and can process various organic composting materials such as livestock and poultry manure, straw, mushroom residue, and kitchen waste. It is especially suitable for bio-organic fertilizer production—the entire process involves low-temperature granulation without damaging the activity of biological bacteria, resulting in a live bacteria survival rate of over 95%. Meanwhile, through process fine-tuning, it can also be compatible with the production of organic-inorganic compound fertilizers, micronutrient fertilizers, and other types, significantly improving equipment utilization and adapting to different fertilization needs for field crops and fruit and vegetable cultivation. It is worth noting that this production line is not suitable for high-concentration compound fertilizers, pure inorganic fertilizers, or other low-viscosity raw materials that require drying; precise matching of production requirements is necessary when selecting the model.

High efficiency, energy saving, and environmental protection are its core competitive advantages for global promotion. The production line eliminates the need for a drying section, consuming only 20-30 kWh per ton of fertilizer, only one-fifth of traditional rotary drum granulation lines, significantly reducing production energy consumption and costs; it can directly process raw materials with a moisture content of 25%-45% without pre-drying, saving investment and energy consumption in drying equipment. In terms of environmental protection, the accompanying pulse dust collector effectively controls dust emissions, meeting environmental standards worldwide, while also promoting the resource utilization of organic solid waste, aligning with green agricultural development policies.

Flexible capacity configuration adapts to different scales of production needs. From 1-3 t/h production lines suitable for small farms, to large-scale lines of 8-15 t/h required by large enterprises, and customized lines of 15-25 t/h for group-scale mass production, the equipment can precisely match the production scale of different regions worldwide. The equipment has a simple structure and low maintenance costs; a medium-sized line requires only 500-800 square meters of plant space, and can be put into operation within 15-20 days after installation and commissioning. This lowers the entry barrier for small and medium-sized organic fertilizer enterprises and provides a high-efficiency mass production solution for large enterprises.

The efficient and stable operation of the horizontal mixing extrusion granulation production line relies on scientific technical principles, reasonable process configuration, and standardized operation management. As the core equipment of the organic fertilizer cold granulation process, its core technology lies in achieving raw material agglomeration and shaping through mechanical force. Simultaneously, its modular process design adapts to different production needs. Mastering its technical points and practical operating procedures is key to ensuring production efficiency and product quality.

The core working principle is simple and efficient. A double-helix stirring shaft inside the horizontal main unit is driven by a motor to rotate at high speed. The raw materials are vigorously stirred and kneaded within the cylinder to form a uniform material agglomeration. Under axial thrust, this agglomerate moves towards the discharge port and is ultimately forced through the screen openings by radial pressure applied by the extrusion scraper and discharge screen, forming cylindrical granules. The particle size can be adjusted via the screen (2~12mm). The entire granulation process is cold-granulation without heating or the addition of additional binders, perfectly adapting to the physical characteristics of organic fertilizer raw materials. This is its core advantage, distinguishing it from other granulation processes.

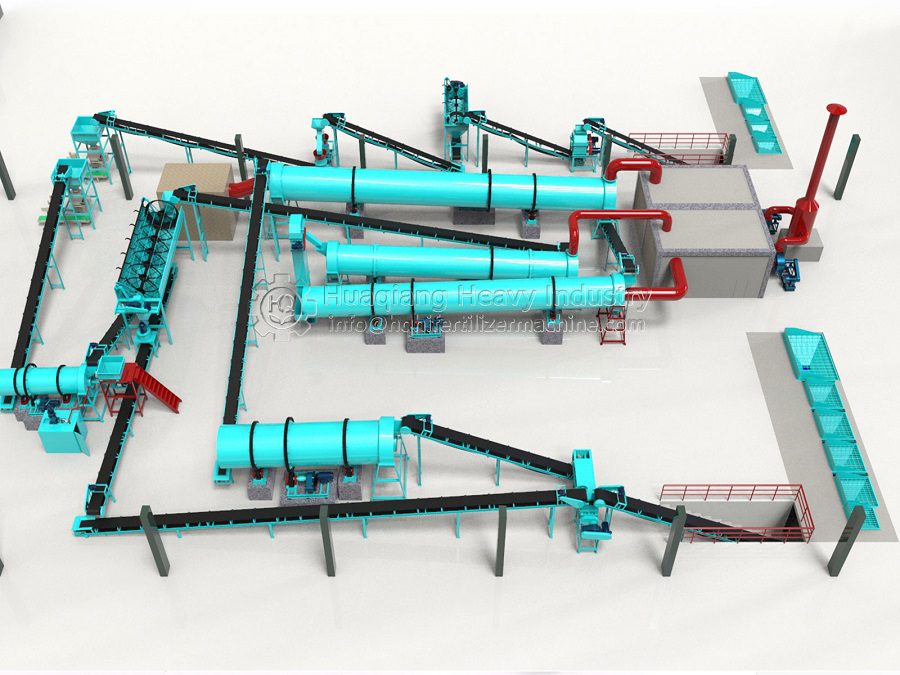

The production line adopts a modular process design, offering two flow options: a basic flow and a high-end flow. The basic flow covers core steps such as raw material crushing, mixing, granulation, screening, and packaging, meeting production standards at a low cost. The high-end flow adds equipment such as a drum polisher, air cooler, and palletizer, improving granule roundness and storage and transportation stability, adapting to large-scale mass production needs. The core equipment includes a horizontal mixing and extrusion granulation unit (accounting for 60% of the equipment investment), a pre-treatment crusher and mixer, and a post-treatment vibrating screen. Auxiliary equipment can be selected as needed to avoid ineffective investment.

Scientific equipment selection and standardized operation are key to successful production. Equipment selection should be based on production capacity and product positioning. For production lines primarily focused on bio-organic fertilizer or those pursuing low-cost production, this production line should be prioritized. Medium-sized lines can be equipped with polishing machines to improve granule quality, offering the best cost-effectiveness. During operation, raw material control is paramount. The organic fertilizer compost must be crushed to ≤5mm, with a moisture content controlled between 30% and 35%, and the coarse fiber content not exceeding 30%. Equipment operation requires adjusting the mixing shaft speed according to the raw material type and regularly checking screen wear. Simultaneously, environmental protection equipment is necessary to ensure that dust and odor emissions meet standards.

In the future, the production line is being upgraded towards intelligence and integration, realizing automatic parameter adjustment and remote monitoring through a PLC control system, integrating multiple processes to improve production efficiency, and expanding the processing capacity of raw materials such as municipal sludge and kitchen waste, further aligning with the global trend of solid waste resource utilization and green agricultural development.

Diverse Granulation Pathways in Modern Fertilizer Plants

The horizontal mixing extrusion granulation line exemplifies one of several fertilizer granulation processes within a professional fertilizer manufacturing equipment portfolio. This method is ideal for high-moisture organic materials and is central to a dedicated bio organic fertilizer production line, where it preserves microbial viability. For mineral-based production, a different set of technologies is employed. An npk fertilizer production line typically starts with a npk blending machine for powder formulation, followed by granulation. Here, a disc granulation production line using a disc granulator is a common wet agglomeration method, or a double roller press granulator for dry compaction.

Selecting the right fertilizer raw material processing machinery and equipment is fundamental to plant design. An integrated fertilizer manufacturing plant equipment setup may include both organic and NPK lines. For instance, raw materials might first be processed in an organic fertilizer production line fed by a windrow composting machine, while a parallel npk fertilizer line handles inorganic blends. The key is matching the granulation technology—whether extrusion, disc granulation, or roller pressing—to the physical and chemical properties of the feedstock to optimize efficiency, product quality, and energy consumption.

This technological diversity allows manufacturers to build versatile facilities capable of producing a wide range of organic, bio-organic, and compound fertilizers, meeting the specific nutritional and logistical demands of different agricultural markets.