Cow manure organic fertilizer manufacturing process:

At present, there are many methods in the organic fertilizer production line, such as disc, drum, and extrusion, and each of these methods has its own advantages and disadvantages. The advantages of the disc granulator are intuitive operation, simple control, high ball formation rate, less material return, less wearing parts of the equipment, and less maintenance; its shortcoming is the small processing capacity of the single machine.

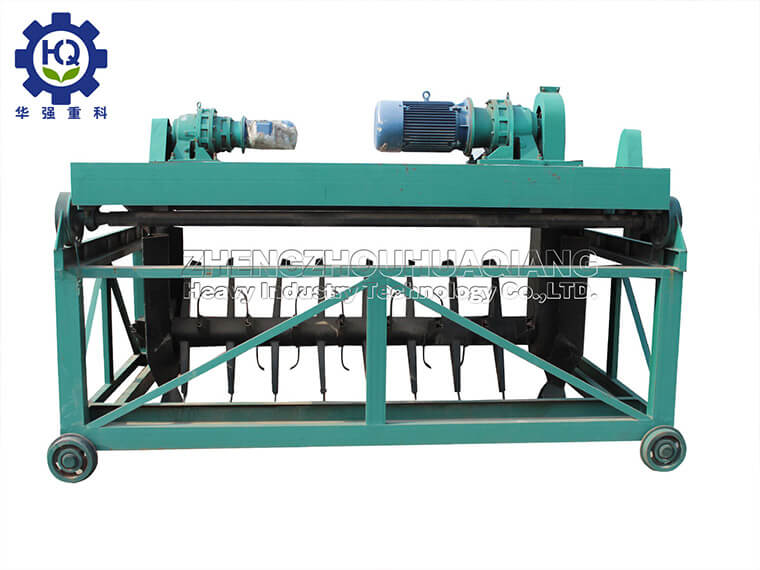

Installation and commissioning of rotary drum granulator:

After the drum fertilizer granulator machine arrives at the factory, it is installed in conjunction with the granulation process, indicating the elevation and horizontal position, and inclined installation. The general inclination is 2-5 degrees (can be adjusted by the user). The machine bracket and The transmission frame has anchor holes and can be installed on concrete.

Features of rotary drum granulator:

It has the large capacity, low power consumption and maintenance costs.

The balling rate is 70%, with small amount of return material, small size of feed back and can be re-granulation.

Zhengzhou Huaqiang can provide the best service to you and help our clients gain profit in quickly.

We will provide the most environmentfriendly and safe products with high quality at most favorable fertilizer granulator machine price for the customer with perfect after service.