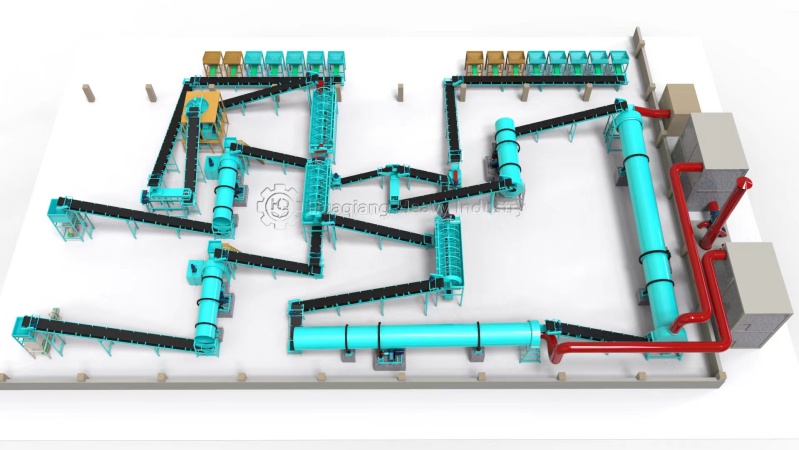

The chicken manure organic fertilizer production line uses fresh chicken manure as raw material, undergoes a series of processing treatments, and produces high-quality chicken manure organic fertilizer. There are two steps required for processing commodity organic fertilizers: the pre fermentation and treatment part and the deep processing granulation part. The complete production line equipment includes fermentation stacker, forklift silo, crusher, mixer, granulation machine, dryer, cooling machine, screening machine, coating machine, packaging machine, belt conveyor, and other equipment.

Process flow of organic fertilizer granulation production line configuration:

1. The processing of organic fertilizers mainly involves collecting raw materials, then proportioning them according to the required formula, adjusting the moisture and carbon nitrogen ratio of the raw materials, and starting fermentation.

2. Fine crush the fermented raw materials to achieve the required particle size before granulation.

3. Add the crushed raw materials to the corresponding auxiliary materials and stir evenly.

4. Organic fertilizer granulator is used to granulate the mixed raw materials. The granulator includes disc granulator, new wet granulator, polishing machine, drum granulator and other models. Appropriate granulators are selected according to the characteristics of raw materials.

5. The prepared particles are transported to an organic fertilizer dryer, and their original moisture content is dried to below 15% to increase their particle strength.

6. The dried particles are transported to the organic fertilizer cooler and quickly cooled and shaped by natural or forced cold air.

7. There may be some oversized or undersized unqualified particles in the produced particles, which will be screened out using a screening machine. The unqualified particles will be returned to the corresponding process to remake the particles, and the qualified particles will enter the next process.

8. Use a coating machine to evenly spray a layer of coating agent on the periphery of the particles, which can effectively supplement the trace elements of the product and improve its brightness and fullness.

9. Qualified products are transported to a fully automatic packaging scale for weighing, packaging, and warehousing, and all processing processes are completed.

How much is the equipment for the chicken manure organic fertilizer production line

The equipment for a simple chicken manure organic fertilizer production line is within 100000 yuan, and the customer requirements vary. The organic fertilizer production line we configure for each customer also varies. The low configuration of the chicken manure organic fertilizer production line only requires a crusher, mixer, granulator, screening machine, and packaging machine. This is a basic configuration, and equipment is added according to the actual needs and requirements of customers. Therefore, the equipment prices for the entire chicken manure organic fertilizer production line range from tens of thousands to hundreds of thousands.

.jpg)

.jpg)