The most important way to solve urban environmental problems is to solve the pollution caused by the aquaculture industry, which is also a challenge that most cities face and find difficult to solve. To completely solve such problems, it is absolutely necessary to have organic fertilizer equipment. There are farmers of all sizes in every city, and the phenomenon of excessive accumulation of livestock manure is common in any city. How to centrally utilize them is the top priority in solving urban environmental problems.

The production methods of organic fertilizer can be divided into: raw material collection, raw material ratio, raw material moisture control, raw material fermentation, raw material crushing, raw material drying, granulation, packaging into bags, etc. The detailed process of the complete organic fertilizer production line is as follows:

1. Firstly, build a fermentation tank based on the customer’s usage site, which can also have multiple tanks per machine.

2. Secondly, raw materials such as animal manure are fermented and decomposed, with a fermentation cycle of 7-10 days and flipped every 2 days. The entire fermentation process can kill harmful bacterial communities inside, which is also an important part of the entire organic fertilizer production process.

3. After the organic fertilizer raw materials are fermented and decomposed, they are crushed by a semi wet material crusher (the finer the fermented materials are crushed, the more rounded the particles are produced).

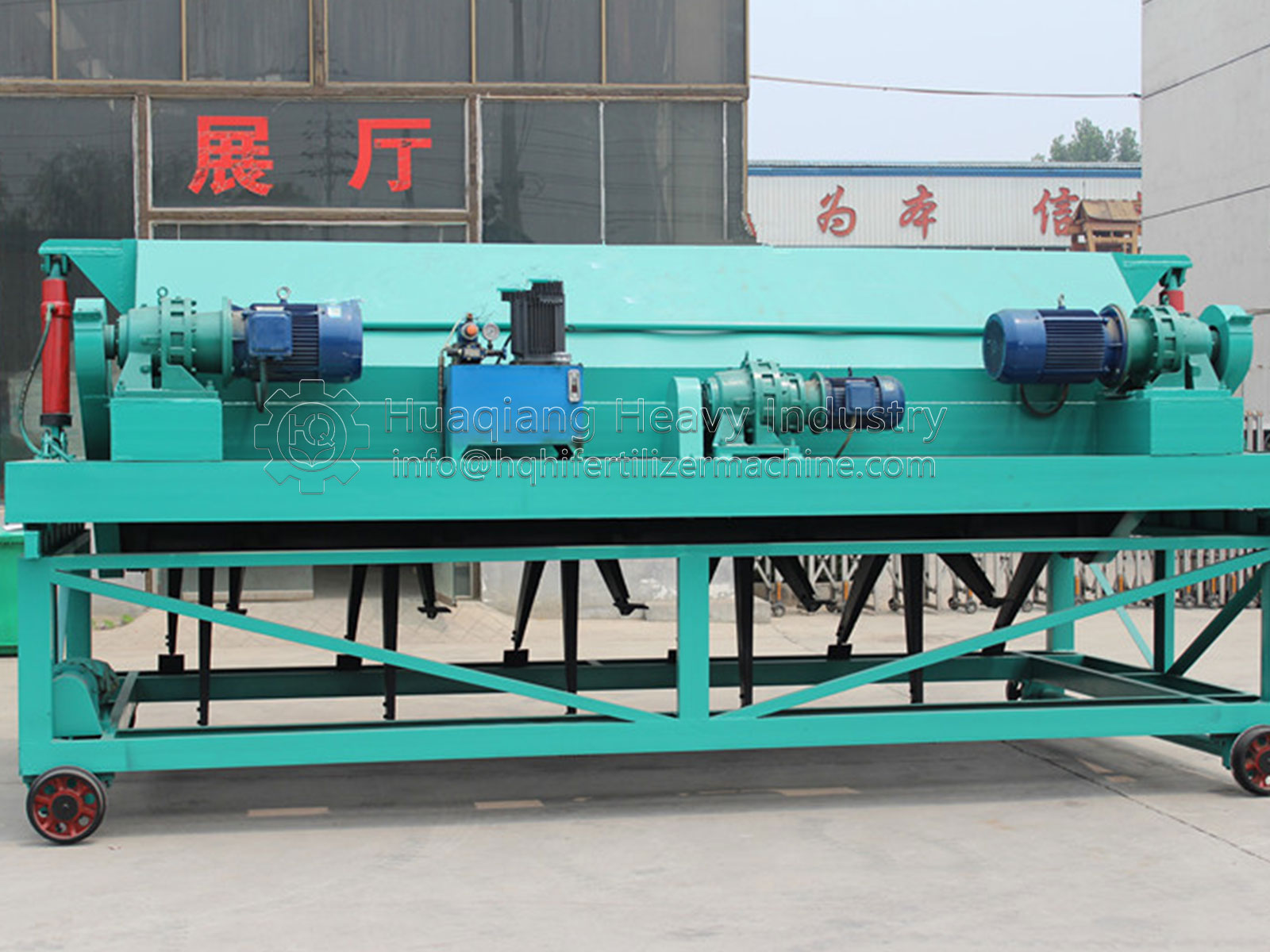

4. Adding elements such as nitrogen, phosphorus, and potassium, using bidirectional spiral stirring for more uniform mixing, and mechanical granulation after uniform mixing of the prepared material. Pairing with raw materials is one of the important processes in organic fertilizer production to improve the quality of the fertilizer.

5. Use an organic fertilizer granulator to generate the required granular granulation of the mixed raw materials.

6. The organic fertilizer particles are sent to the dryer through a belt conveyor to dry the raw materials, and the moisture content of the dried raw materials does not exceed 30.

After the raw material undergoes the drying step to obtain high-temperature energy, the next step requires low-temperature cooling. Since water cannot be used for cooling, it is necessary to separate the contact between the material and water through the organic fertilizer cooling machine equipment.

8. The screening machine is used to screen out unqualified organic fertilizer particles, screen out coarse materials and then refine them. Fine materials can be granulated, with a more beautiful appearance and higher granulation rate.

9. For users with higher requirements, a layer of coating agent can be added outside the particles to make their appearance more rounded and shiny.

10. Finally, pack.

The vigorous promotion and use of organic fertilizer production lines can effectively solve this problem. Organic fertilizer equipment is used to ferment and decompose animal manure into organic fertilizer, which can be reused on crops and effectively improve crop quality. It can achieve the recycling of agricultural resources and effectively solve environmental pollution problems.

.jpg)

.jpg)

.jpg)