In the early 1990s, China introduced foreign tank fermentation technology from foreign countries. On the basis of integrating various treatment methods, combined with the characteristics of China’s agricultural and animal husbandry business model, it adopted a comprehensive treatment of solar aerobic fermentation technology.

From the perspective of practicality and cost control, the trough fermentation system is the preferred process for organic fertilizer production line. Here we make a comparison and find that the self-propelled compost turning machine is flexible but has a large area; the fermentation cycle of the fermentation tank is short, but the cost is not suitable for popular demand. At present, the more widely used are the groove type compost turning machine, and the high-grade ones include the double-spiral stacker and the chain plate stacker, etc. There are many types of products, which can be ordered according to their own needs.

The use of solar energy for aerobic fermentation is a very important part of the organic fertilizer production line. During this period, the treatment of organic solid waste must solve the problems of drying, fermentation, sterilization, deodorization, etc., and finally obtain higher economic benefits at a lower cost. Before fermentation, various raw materials to be fermented are mixed in a certain proportion to meet the fermentation conditions such as moisture and carbon-nitrogen ratio, and the purpose of shortening the fermentation cycle is finally achieved to achieve the optimal fermentation effect.

In order to make organic solid waste into efficient organic fertilizer, it must be fully fermented and matured. The application of organic solid waste without fermentation or incomplete fermentation to the land is extremely harmful to crops. It can decompose in the soil to generate heat and carbon dioxide gas and other harmful substances, which seriously affects crop germination and crop root growth. The organic solid waste can achieve the purpose of eliminating harmful substances, germs, and reducing odor after full fermentation. At the same time, it occupies less space, increases the humus uniformly, and is more convenient to use when fertilizing. Fully fermented and decomposed is a necessary process to increase the effective ingredient humic acid in organic fertilizers. Organic raw materials made from organic fertilizers directly added to inorganic fertilizers without being processed in this step are organic-inorganic compound fertilizers. Low phytic acid is not good for crops and soil.

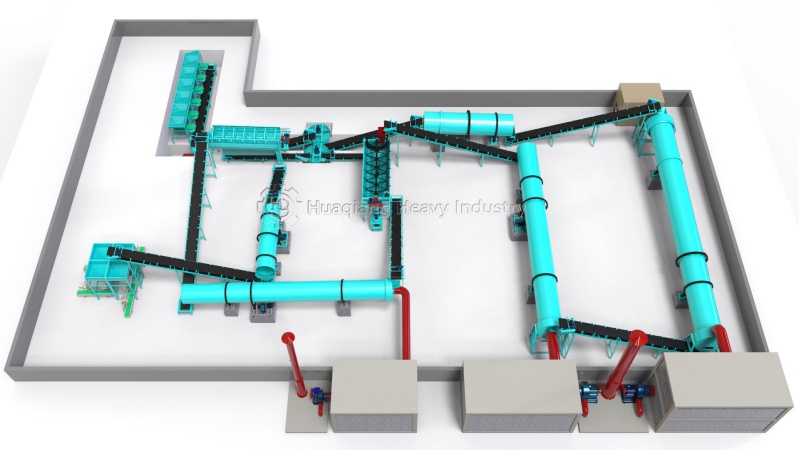

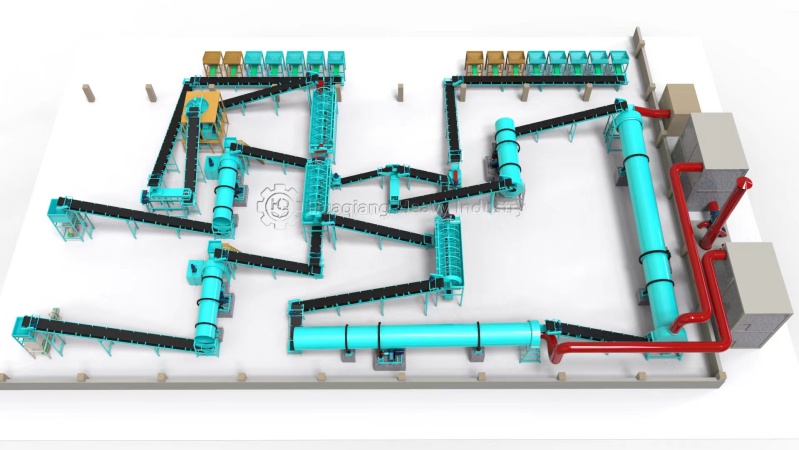

Process flow of a complete set of pig manure organic fertilizer production line

The organic fertilizer production line is an equipment for mass production of bio organic fertilizers, which plays a very important role in the development of agriculture. The organic fertilizer equipment ferments crop waste and livestock waste, such as straw, corn cob, distiller’s grains, chicken manure, pig manure, and other manure containing organic substances, to produce organic fertilizer containing a large number of microbial strains. The microbial strains in the finished organic fertilizer can improve the soil structure, increase the content of organic matter in the soil, and use chemical fertilizers and compound fertilizers to greatly increase crop yield. After a certain process flow of fertilizer production line, high-quality organic fertilizer can be processed. Below is a complete set of production process flow of organic fertilizer production line:

1. The raw materials, auxiliary materials, and fermentation agents are pre mixed evenly through the equipment in proportion, with a moisture content of about 60. They are transported by conveyor belts and distributed to the fermentation tank through shuttle belt distribution machines.

2. In order to fully ferment the materials in the fermentation tank, a chain plate tipping machine is used to flip and shift the materials. At the same time, the aeration system is used to aerate the bottom of the tank, allowing the materials to undergo aerobic fermentation.

3. The fermentation of the material is basically completed in the fermentation tank for about 7 to 10 days. Under the flipping displacement of the flipping machine, the material is flipped to the discharge end, and then transported to the aging tank through the pool changing discharge machine, discharge belt conveyor, and shuttle type distribution machine for secondary fermentation during aging, so that the material matures thoroughly.

4. The decomposed materials are transported to the granulation workshop through conveyor belts, and are screened and processed by drum screening machines and vertical crushers to remove large blocks of materials;

5. The screened materials and other inorganic nutrients are transported proportionally to a dual shaft paddle mixer using a batching belt scale and mixed evenly. Uniformly mixed materials can be packaged as powder products, and can also be granulated by adjusting the moisture content to around 40.

6. Materials with a moisture content of about 40% are produced into columnar semi-finished products through a organic fertilizer granulator, which are then shaped into spherical granular semi-finished products by a shaping machine. They are transported by a conveyor belt to a tubular dryer for low-temperature drying, and then screened and cooled by a cooling screening machine to reduce the moisture content to between 15 and 30. Packaging can also be carried out after further coating treatment as needed;

7. The finished particles are transported to the packaging workshop through bucket elevators and finished product conveyor belts, and are packaged using automatic measuring packaging scales and manually stacked.

The organic fertilizer production line not only solves the environmental pollution caused by the storage of agricultural breeding wastes, but also improves the soil structure and increases crop yield. Recycling resources plays a crucial role in promoting sustainable development in agriculture.

Fertilizer processing process of biological manure organic fertilizer production line

The entire production process of biofertilizer project is divided into ten steps, each of which will directly affect the quality of bio-organic fertilizer production line, which cannot be reduced in production..jpg)

The following is the process of producing biological organic fertilizer:

1. The raw materials such as animal manure must be fermented and rotted. During the entire fermentation process, harmful bacteria inside can be killed, which is also the most important in the entire organic fertilizer manufacturing process.

2. Secondly, the semi-wet material crusher of organic fertilizer crushing equipment is used to preliminarily decompose the raw materials.

3. Ingredients are a key step in fertilizer production. Its main function is to add appropriate ingredients in proportion to make the organic fertilizer rich in organic matter and improve its quality.

4. Granulation is required after the materials are evenly mixed, which is also the most important part of the whole process.

5. The material gets high temperature during the drying process, and then it needs to be cooled. Because water cannot be used for cooling, a cooling device is needed here.

6. Screening is the need to screen out the unqualified fertilizer, and the unqualified materials will return to the production line for qualified processing and processing again. The screening equipment here has the advantage of being efficient and easy to operate.

7. the stirred material into the required particles, especially suitable for high viscosity materials.

8. The material of the stirring container must meet the requirements of the production process, such as pressure resistance, temperature resistance, medium corrosion resistance, and product cleanness. Due to different materials, the manufacturing process and structure of the stirring container are also different.

9. Conveying is to transport the finished fertilizer to a higher place, and it is prepared for convenient storage.

10. Packaging is the last link in fertilizer equipment. In order to protect the product during circulation, facilitate storage and transportation, and promote sales, the overall name of the container, material, and auxiliary materials used in accordance with certain technical methods; also refers to the above to achieve the above. Objective To apply certain technical methods and other operating activities in the process of using containers, materials and auxiliary materials.

The equipment required for the production of bio-organic fertilizers are fermentation stackers, shredders, mixers, fertilizer granulator machine, dryers, sieving machines, and packaging machines.

Which Organic Fertilizer Pelletizer to Choose for Biological Manure Processing Fertilizer

Bio-organic fertilizer equipment has always been the star product of our factory. There are many production processes for producing bio-organic fertilizer, and each production process has its own characteristics. The key to the production process of biofertilizer project is the choice of granulation method. According to the production process requirements, the current granulation methods commonly used in bio-organic fertilizer are mainly disc granulation and stirring granulation. Due to different requirements of raw materials for different granulation methods, there are differences in the production process of biological organic fertilizer. At present, our organic fertilizer equipment has the following production processes.

Using the disk granulation production process, the raw materials need to be dried to remove a certain amount of water (when drying, the raw materials are sterilized), and then crushed, and then a certain amount of acid and alkali is added to adjust the PH of the carrier and mixed with the inorganic fertilizer part, and sent into The disc granulator sprays a certain amount of bacteria during the granulation process, and the granulated product is dried and sieved at low temperature to obtain the finished product.

The tooth-granulation granulation process is to use the high-speed rotating mechanical stirring force and the aerodynamic force generated thereby to continuously realize the process of mixing, granulating, spheroidizing and densifying the fine powder in the machine, thereby achieving the purpose of granulation. The shape of the particles is spherical, the sphericity is ≥0.7, the particle size is generally between 0.3-3 mm, and the granulation rate is ≥90%. The size of the particle diameter can be appropriately adjusted by the material mixing amount and the spindle speed. Generally, the lower the mixing amount, the rotation speed the higher, the smaller the particles, and vice versa.

From the process flow, the two processes have the same equipment before granulation and the area is about the same, so the difference in investment mainly depends on the fertilizer granulator machine. The same is the case of a 10,000 t / a scale production capacity. 4000 ~ 5000 yuan / set, while the stirring granulator is generally 50,000 yuan / set (the specific price is determined by the specific specifications and the manufacturer’s price is for reference only), and the low temperature dryer is 12-15 thousand yuan / set. Therefore, from the perspective of investment, the disc granulation production process is relatively higher than the extrusion granulation process, and the specific production process needs to be tailored by a professional technical team.

How does the organic fertilizer production line ferment and process raw materials into organic fertilizer

The future development potential of organic fertilizer production lines is enormous. Due to the current agricultural situation in China, organic fertilizer raw materials are abundant and of high quality, and the market demand for organic fertilizer is also large. The scale of use of organic fertilizer is also very wide, whether it is farmland or vegetable cultivation greenhouses, or the beautification of fruit trees, flower gardens, and soil improvement, organic fertilizer is widely used. It also conforms to the national agricultural development policy, indicating that the prospect of organic fertilizer production lines is very broad.

The organic fertilizer production line is composed of many small machinery and equipment, each of which affects, restricts, and complements each other. After a certain process flow, high-quality organic fertilizer can be processed. The production process of the organic fertilizer production line is as follows:

1. The raw materials, auxiliary materials, and fermentation agents are pre mixed evenly through the equipment in proportion, with a moisture content of about 60. They are transported by conveyor belts and distributed to the fermentation tank through shuttle belt distribution machines.

2. In order to fully ferment the materials in the fermentation tank, a chain plate tipping machine is used to flip and shift the materials. At the same time, the aeration system is used to aerate the bottom of the tank, allowing the materials to undergo aerobic fermentation.

3. The fermentation of the material is basically completed in the fermentation tank for about 7 to 10 days. Under the flipping displacement of the flipping machine, the material is flipped to the discharge end, and then transported to the aging tank through the pool changing discharge machine, discharge belt machine, and shuttle type distribution machine for secondary fermentation of aging, so that the material is thoroughly decomposed.

4. The decomposed materials are transported to the granulation workshop through conveyor belts, and are screened and processed by drum screening machines and vertical crushers to remove large pieces of material;

5. The screened materials and other inorganic nutrients are proportionally transported to a dual shaft paddle mixer using a batching belt scale for mixing. Uniformly mixed materials can be packaged as powder products, and can also be granulated by adjusting the moisture content to around 40.

6. Materials with a moisture content of about 40% are produced into columnar semi-finished products through a granulator, which are then shaped into spherical granular semi-finished products through a shaping machine. They are transported by a conveyor belt to a tubular dryer for low-temperature drying, and then screened and cooled by a cooling screening machine to reduce the moisture content to between 15 and 30. They can also be coated and packaged as needed;

7. The finished particles are transported to the packaging workshop through bucket elevators and finished product conveyor belts, and are packaged using automatic measuring packaging scales and manually stacked.

The construction of an organic fertilizer production line has a market opportunity. Nowadays, people are pursuing a high-quality life, and their pursuit of food quality is also increasing. Under the strong call of national policies, more and more farmers are applying organic fertilizer, which has a long-lasting effect and contains various nutrients that crops need. Maintaining fertilizer and water can also prevent and control diseases and pests. The small organic fertilizer production line has a very broad profit margin and is an ideal project.

Properly maintain the organic fertilizer granulator to prolong the service life of the equipment

Organic fertilizer granulator machine occupy an important position in the entire organic fertilizer production line. Organic fertilizer granulators are divided into drum granulators, flat die granulators, extrusion granulators, disc granulators, etc. Although the working principles are different, the daily maintenance methods are basically the same. We do a good job of organic fertilizer The purpose of the daily maintenance of the granulator is to reduce and avoid equipment damage and economic losses caused by organic fertilizer production operations. So how to maintain the organic fertilizer granulator in daily use?.jpg)

Maintenance method of organic fertilizer granulator machine:

1. Keep the work site clean. After each test of the organic fertilizer equipment, the residual rubber sand inside and outside of the granulating leaves and the granulation pot should be completely removed. The rubber sand and the flying objects scattered or splashed on the organic fertilizer equipment should be cleaned. The exposed working surface of the machine is wiped clean, coated with anti-rust meat paint, and covered with a corresponding cover to prevent secondary intrusion of dust.

2. Organic fertilizer equipment has no external refueling holes. Gears and worm gears are lubricated with special grease for organic fertilizer equipment. The upper gear and the lower gear should be filled with butter three times every season, and the moving gear box cover and the transmission gear cover can be opened separately when refueling). Oil should be lubricated from the sliding surface between the supporting gear box and the sliding surface of the bracket. Worm gearboxes and bearings have been filled with transmission butter when they leave the factory, but the gearbox machine should be thoroughly cleaned after every one year of use and all protective lubricants replaced.

3. Always pay attention to the operation of organic fertilizer equipment. There should be no serious abnormal noises and no metal friction sounds. If any abnormality is found, stop using it immediately and inspect it. Use it only after troubleshooting. The reason cannot start the machine. If there is metal friction, check the gap between organic fertilizer equipment first.

4. often check the standard gap between organic fertilizer equipment.

5. When the organic fertilizer equipment is overhauled, the working gap should be re-determined each time, and adjustments should be made multiple times. It can only be used after meeting the standards.

6. If the organic fertilizer equipment cannot be operated by pressing the programmer, check the power supply voltage, whether the power plug socket, connection plug socket, etc. are normal, and check the internal faults of the controller.

Composition of complete equipment for organic fertilizer production line

Livestock and poultry manure is a relatively good quality organic fertilizer. Livestock and poultry manure must be decomposed by a decomposing agent, and the parasites and eggs in livestock and poultry manure, as well as some infectious bacteria, are inactivated and deodorized through the process after decomposing. The production process of livestock manure organic fertilizer is closely related to the equipment configuration of organic fertilizer production line. Generally, the complete set of equipment of organic fertilizer production line mainly consists of fermentation system, drying machine, deodorization and dust removal system, crushing machine, batching system, mixing machine, fertilizer granulator machine, and screening system and finished product packaging system. The production process of livestock manure organic fertilizer roughly includes: raw material selection (livestock manure, etc.) → drying and sterilization → mixing of ingredients → granulation → cooling and screening → metering sealing → finished product storage..jpg)

Performance characteristics:

Production process design of livestock manure organic fertilizer production line includes: 1. Efficient compound strain and its propagation technology; 2. Advanced raw material allocation technology and biological fermentation system; 3. The best special fertilizer formula technology (can be flexibly according to the local Soil and crop characteristics, design the best combination of product formula); 4. Reasonable secondary pollution (exhaust gas and worry) control technology; 5. Design and manufacturing technology for complete sets of process equipment for fertilizer production.

The construction scale of animal manure organic fertilizer production line equipment configuration is generally 30,000 to 100,000 tons per year. Comprehensive consideration must be given to local resources, market capacity, and market coverage. The investment scale and product plan design need to be formulated according to the following conditions: characteristics of raw material resources, local soil conditions, local planting structures and main crop varieties, factory site conditions, and the degree of automation of production.

Double roller granulator for producing organic fertilizers to solve fecal pollution

Green development has now become an important goal. The pollution in our country is very serious, especially in terms of ecology. In the case of numerous livestock farms, the pollution caused by livestock manure is very serious. It not only pollutes the environment and land seriously, but also pollutes groundwater. Therefore, the treatment of livestock manure pollution is very important, And organic fertilizer equipment is specialized in handling livestock and poultry manure, which can effectively solve the pollution of livestock and poultry manure and make it into organic fertilizer. Therefore, organic fertilizer equipment is now recognized by many people.

From the environmental protection situation in the past two years, the country has made great efforts to address environmental pollution, especially soil pollution. Currently, the country is vigorously promoting the use of organic fertilizers, which are generally produced using organic fertilizer production lines. Why use organic fertilizers? Due to the serious soil compaction situation, if left untreated, it will seriously affect the yield of grain, and the use of organic fertilizers is necessary to control soil compaction and make the soil fertile.

It is understood that the production of organic fertilizer mainly involves the organic transformation of livestock waste, food and drug residues, and industrial sludge, ultimately returning them to the field, ensuring that the environmental protection loop does not produce pollution. Expert introduction, Crop straw and other plant residues, livestock and poultry manure, agricultural by-products, household waste, as well as biogas residue, peat, plant ash, sludge, and urban sludge, can all be used as raw materials for organic fertilizers. The use of organic fertilizers can help upstream production enterprises dispose of waste and reduce pollution to the agricultural and animal husbandry industry. On the other hand, compared to fertilizers, organic fertilizers play a crucial role in the development of ecological agriculture

The production process of the double roller granulator is simple, with low energy consumption and large output. Direct granulation of dry powder does not require subsequent drying processes, which is more conducive to the connection and transformation of existing production processes. The particle strength is high, and the increase in bulk density is more significant than other granulation methods. Especially suitable for occasions where the stacking weight of products is increased. The operation flexibility is large, the adaptability range is wide, and the extrusion pressure can be adjusted through hydraulic pressure.

Application of Bio-organic Fertilizer Granulator and Its Advantages in Agriculture

Bio-organic fertilizer is based on organic waste from livestock and poultry manure, crop stalks, agricultural by-products, and food processing. It is equipped with a multi-functional fermentation strain agent to quickly deodorize, rot, and dehydrate, and then add functional biological strain An organic fertilizer containing a certain amount of functional microorganisms processed by an agent.

Bio fertilizer project production line contains the main equipment:

1. Automatic batching system: The automatic batching system is mainly composed of a feeding system, a weighing device, a silo, and a conveyor belt. And the static batching system has both the speed of dynamic batching and the accuracy of ordinary static batching (0.2%).

2. New type organic fertilizer granulator machine: It is designed and manufactured by wet continuous pusher granulation. This machine can not only granulate a variety of organic materials, especially for coarse fiber materials that are difficult to granulate using conventional equipment.

3. Horizontal mixer: This series of horizontal mixer is a new generation of mixing equipment developed by our company. The machine has high mixing degree and low residual amount, which is suitable for mixing organic fertilizer and inorganic fertilizer.

4. Drum sieve: The machine uses a combined sieve for easy maintenance and replacement. Its simple structure, convenient operation and stable operation are ideal equipment for compound fertilizer production.

5. Conveyor: suitable for coal, metallurgy, mining, chemical industry, building materials, docks, warehouses, construction sites, etc. for conveying bulk materials or bag-like articles, especially suitable for use in environments such as fertilizer plants and cement plants where manual loading is required Save a lot of staff.

6. Dryer: This machine has the characteristics of beautiful appearance, simple operation, low energy consumption, long life, uniform drying and convenient maintenance. It is a relatively advanced compound fertilizer drying equipment in China.

7. Hot blast stove: The hot blast stove boiler adopts backwater ejection and other technologies to solve the problems of tube plate cracks in boiler shell boilers, drum bulging under the drum, water wall burst, low thermal efficiency, insufficient output, and poor coal adaptability.

8. Packaging scale: The packaging scale is mainly composed of automatic quantitative packaging scale (consisting of storage hopper, feeder, weighing bag hopper, kneading mechanism, computer control, pneumatic execution part, etc.) and optional parts (conveyor, sewing Mouth machine / heat sealing machine).

Advantages of Drum Granulator in NPK Fertilizer Production Line

NPK fertilizer production line with steam drum granulation production is a process to achieve thermal granulation, by raising the temperature of the material, increase the solubility of the salt of the granulation water system, so as to achieve low moisture content to meet the needs of the material grain ingenuity of the liquid phase, reduce the thermal energy consumption of the drying process, improve the production capacity of equipment. Therefore, the quality of granulation performance of compound fertilizer equipment is one of the keys to determine the yield and quality of compound fertilizer produced by rotary drum granulator.

Next, Zhengzhou Huaqiang Heavy Industries will analyze the advantages and disadvantages of rotary drum type fertilizer granulator machine in the NPK fertilizer production line for you.

The advantages of rotary drum granulator in the NPK fertilizer production line

1, save the urea concentrate granulation, packaging, transportation and other costs, but also eliminate the solid urea compound fertilizer when broken, solid material meter, transportation and other troublesome operations.

2, urea solution directly involved in granulation, can make compound fertilizer production line granulation material granulation temperature from about 40 degrees C to about 60 degrees C, granulation moisture from 5% to 2.5%, greatly reducing the drying load.

3, the use of urea solution stickiness, in the granulation machine to help the material granulation, improve the granulation rate of the material, so that its production capacity increased by about 30%, the corresponding reduction of power consumption 30%.

4, compound fertilizer equipment products from the original 12N to 30N, the finished moisture from 2.0% to 1.00%, the appearance of the particles improved, the block situation can be slowed down.

The disadvantage of rotary drum granulation in the NPK fertilizer production line

1, anti-material more;

2, dust large;

3, power consumption is large;

4, the particles are not smooth and round enough;

5, compound fertilizer production line operating environment is not good.