More and more organic fertilizer to be used in agriculture,and the using of the organic fertilizer has some benefical to the sustainable development of agriculture.The equipment of the organic fertilizer production line has truly realized the development of agricultural cycle.The agricultural organic waste is harmless treated by the equipment of the biological organic fertilizer production line,The new equipment technology is more conducive to the harmless treatment.The organic fertilizer compost is decomposed and fermented.The use of the organic fertilizer machine to process the organic fertilizer does not necessarily require the manure of livestock,chicken,pig or wheat straw or corn straw mixed farm manure.Pig manure,using harmless treatment,adding microbial organic fertilizer fermentation compost fermentation,production of microbial organic fertilizer,organic fertilizer production line equipment is the most ideal harmless treatment method of agricultural waste.

The equipment of the organic fertilizer production line solves the environmental pollution and uses the renewable resources.Organic fertilizer production line technology is planned to gradually promote the use of compost and chemical fertilizer,mainly compost,supplemented by chemical fertilizer,and then slowly reduce the amount of chemical fertilizer,which it is to be produced by using the npk fertilizer production line,so organic fertilizer production line can achieve real circular agriculture,green agriculture,sustainable agriculture.

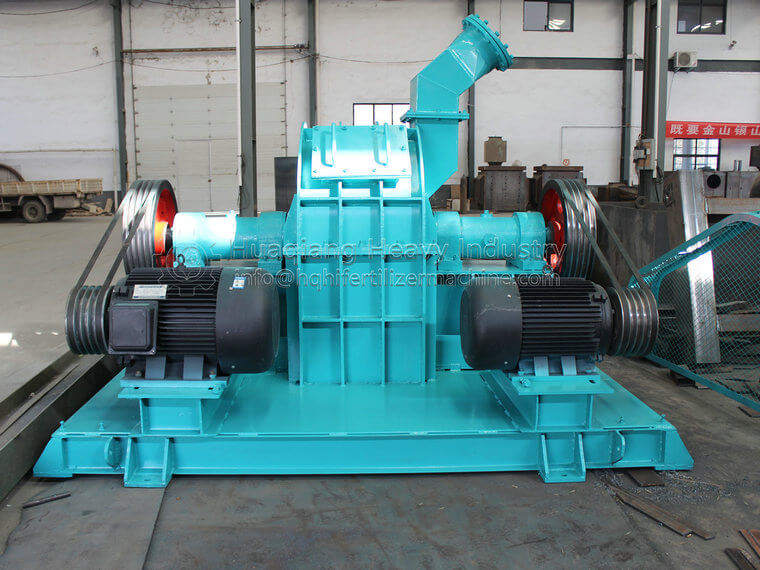

When producing the fertilizer into granulator,the fertilizer granulator machine is necessary in the fertilizer manufacturing process to finish the granulation process.In the fertilizer manufacturing process,the fertilizer machine manufacturers designed all different type and series fertilizer production line,which it is to be equipped with different type fertilizer equipment to finish the production process.For example,the biofertilizer project is also to be designed for producing the bio organic fertilizer granulator.By using the fertilizer granulator machine to make organic fertilizer granulator not only improve the working efficient,it also simplify the production process of the organic fertilizer.