Bio organic fertilizer production line is the key equipment to realize the production of pollution-free agricultural products. It is required to have strict requirements on the environmental quality of the producing area (atmospheric environment, agricultural irrigation water, processing water and soil quality), and also put forward corresponding requirements on the input raw materials of bio organic fertilizer production line. The following four types of fertilizers are allowed for pollution-free production:

1. Fertilizers produced by bio organic fertilizer production line: compost, manure, biogas fertilizer, green manure, crop straw, cake fertilizer, humic acid fertilizer, amino acid fertilizer, commercial organic fertilizer, bone meal, agricultural and livestock processing waste, sugar factory waste, etc.

2. Inorganic fertilizer: mineral phosphate fertilizer, mineral potassium fertilizer, compound fertilizer and nitrogen fertilizer.

3. Trace element fertilizer: copper, iron, boron, zinc, manganese, molybdenum and other trace elements and beneficial element fertilizer.

4. Chemical fertilizer must be used together with organic fertilizer, and large element fertilizer must be used together with medium and trace elements. The economic and rational application of nitrogen fertilizer should be determined according to the level of soil fertility and target yield. The application method should be applied deeply to reduce the volatilization loss and leaching loss of nitrogen. Phosphorus and potassium fertilizer should be applied on the basis of soil measurement, targeted combined application of trace elements, and the use of biological fertilizer is advocated.

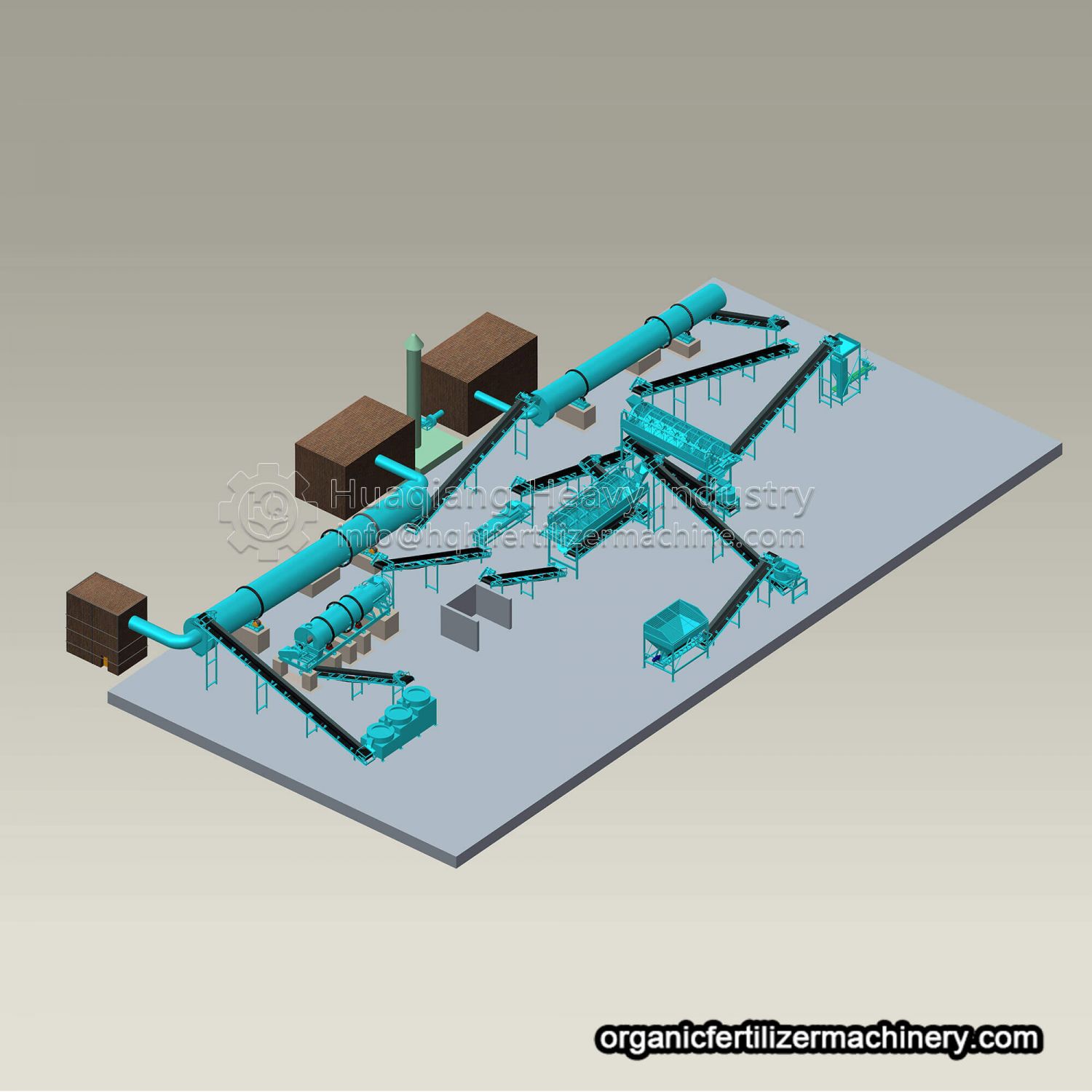

How much is a set of granular organic fertilizer production line with an annual output of 100000 tons? In fact, the organic fertilizer production line is not the fixed equipment in our imagination, but needs to be determined according to the site and materials. Just as chicken manure has more water, it is necessary to reduce water during fermentation. Corn cobs broken by straw can be added, otherwise it will not be granulated, while sheep manure is dry. When the water volume is well controlled, it can be granulated directly without straw, and the price of organic fertilizer equipment with different output is also different. The annual output of 100000 tons of manure organic fertilizer production line needs more than one million yuan.

.jpg)