Granulation technology is a processing technique that transforms powdered, lumpy, or liquid raw materials into granular products of specific size, strength, and shape through physical, chemical, or biological methods. Its core purpose is to optimize the characteristics of raw materials and solve problems such as dust generation, difficulty in storage and transportation, and uneven mixing of powdered materials.

The core value of granulation technology lies not only in improving the physical form of materials but also in enabling precise control of nutrients or components. In the agricultural field, powdered fertilizers, after granulation, become uniform in size and have moderate strength, preventing scattering during application and improving utilization. It also allows for the proportional mixing of multiple nutrients during granulation, enabling balanced fertilization.

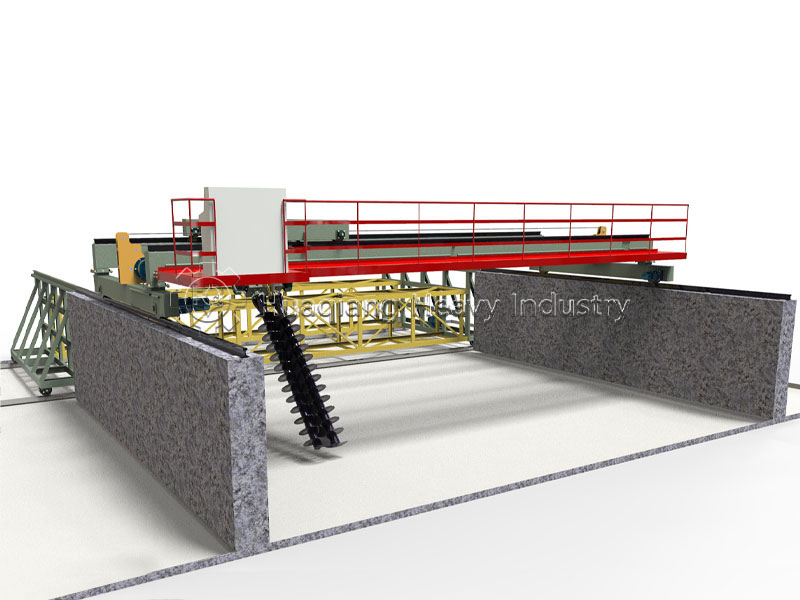

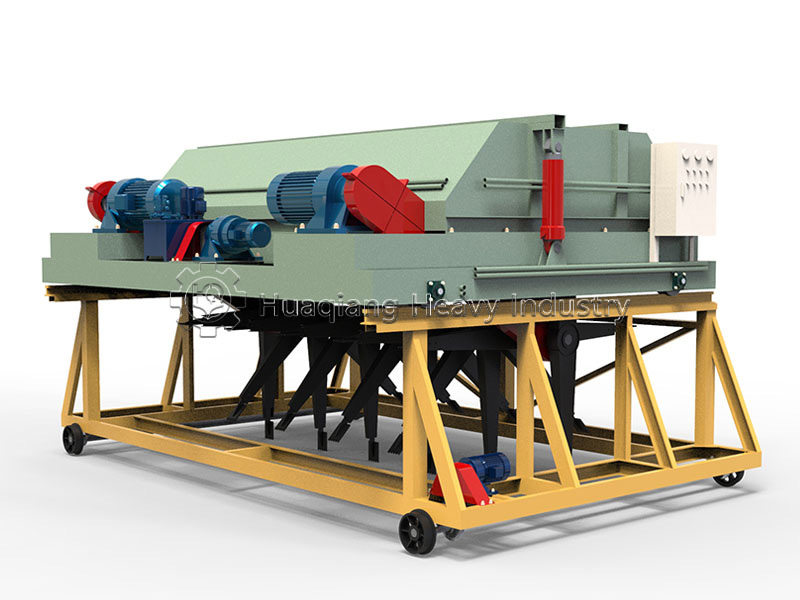

Mainstream granulation technologies are divided into two categories: physical granulation and chemical granulation, with physical granulation being the most widely used. Physical granulation relies on mechanical force or physical action for shaping. Common types include rotary drum granulation,double roller press granulation, and disc granulation technology. For example, rotary drum granulators use centrifugal force and friction to roll and shape the material, while double roller press granulators use high pressure to densify powdered materials without requiring excessive binders. Chemical granulation, on the other hand, utilizes chemical reactions to produce granular products from raw materials and is mostly used in the production of specific chemical products.

In addition to agricultural fertilizer production, granulation technology is also widely used in pharmaceutical tablet formation, food and feed pellet processing. With technological advancements, granulation technology is increasingly focused on environmental protection and efficiency, further improving processing stability and product quality.