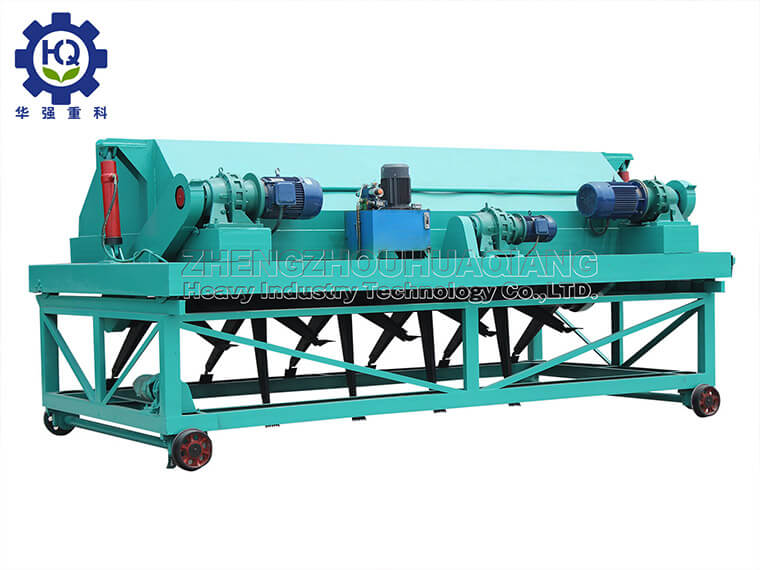

Pig manure Organic fertilizer granulator is also called new wet Organic fertilizer agitator granulator. It is used for granulation of various organic substances after fermentation, breaking through the conventional organic granulation process. Before granulation, the raw materials do not need to be dried or crushed, and spherical particles can be processed directly with ingredients, which can save a lot of energy.

Working principle of pig manure Organic fertilizer granulator. The particle shape is spherical, with a sphericity of ≥ 0.7, a particle size generally between 0.3 and 3 millimeters, and a particle formation rate of ≥ 90%. The size of the particle diameter can be adjusted appropriately by the material mixing amount and the spindle speed. Generally, the lower the mixing amount, the higher the rotation speed, and the smaller the particle, and vice versa.

Features of new wet Organic fertilizer agitator granulator:

1. The produced particles are spherical.

2. Realize organic granulation.

3. By utilizing the characteristic of organic particles being able to embed and grow with each other under a certain force, no adhesive is required during granulation.

4. The granules are solid, and the new wet Manure can be sieved after granulation by a toothed granulator, reducing drying energy consumption.

5. The organic matter after fermentation does not need to be dried, and the moisture content of the raw material can be between 20-40%.

Working principle: the new wet Manure mixing tooth granulator uses the high-speed rotating mechanical mixing force and the resulting aerodynamic force to enable the continuous mixing, granulation, spheroidization, densification and other processes of fine powdery materials in the machine, so as to achieve the purpose of granulation. This granulation method results in higher ball forming rate, more beautiful particles, and energy saving.

The pig manure Organic fertilizer granulator is specialized for the granulation of Manure, raw material, livestock manure, feces, compost, green manure, sea manure, cake fertilizer, peat, soil manure, three wastes, microorganisms and other urban domestic waste organic fermentation fertilizers. The particles are pellets. The qualified granulation rate of the machine is up to 80-90%, which is suitable for many different formulations. The compressive strength of Manure is higher than that of disc and drum, and the large ball rate is less than 15%. The particle size uniformity can be adjusted through the stepless speed regulation function of the machine according to user requirements. This machine is suitable for direct granulation of Manure after fermentation, saving drying process and greatly reducing manufacturing cost.

.jpg)

.jpg)

.jpg)

.jpg)