How to build a fully automatic organic fertilizer production line in the farm

The scale of livestock farms in China is becoming larger and larger, and the feces produced every day are difficult to be treated. The feces of livestock and poultry farms are treated innocuously through the equipment of the production line for processing organic fertilizer in livestock and poultry farms, and the feces of livestock and poultry farms are comprehensively utilized to prevent the pollution of the feces to the environment, while promoting the sustainable development of the aquaculture industry.

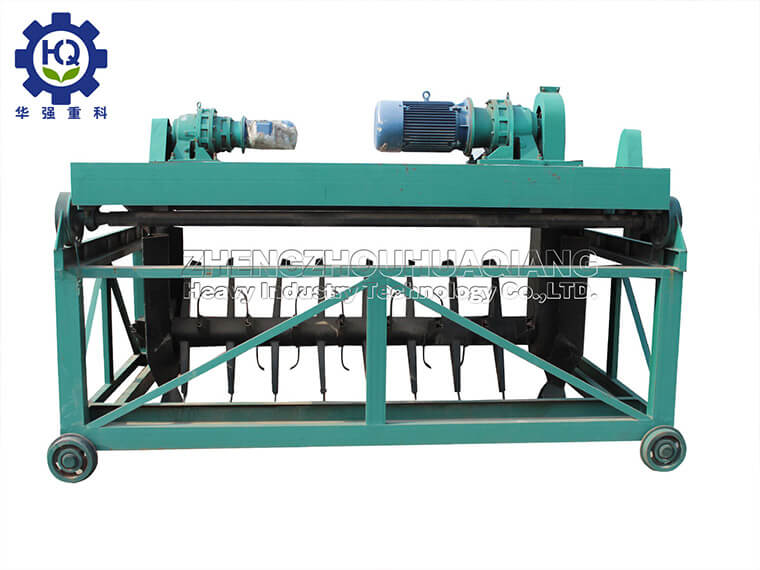

The production of organic fertilizer by livestock manure fermentation requires good (consumption) oxygen fermentation. Therefore, the oxygen supply measures should be increased during the operation process, so as to achieve uniform mixing, frequent turnover and ventilation. Otherwise, it will lead to anaerobic fermentation and odor, affecting the fertilizer effect. Fermentation is complete. Generally, 48 hours after pig manure is piled up, the temperature rises to 50~60 ℃, and the temperature can reach above 65 ℃ on the third day. At this high temperature, it will be overturned once by the organic fertilizer fermentation tipper. Generally, there will be two times of high temperature above 65 ℃ during the fermentation process. The fermentation can be completed after two times of overturning, and the fermentation can be completed within a week or so normally. The material is dark brown, and the temperature begins to drop to normal temperature, indicating that the fermentation is complete.

The complete set of equipment configuration includes fermentation equipment, pulverizer, mixer, granulator, dryer, cooler, screening machine, coating machine and packaging machine, as well as conveyors for material transportation between equipment. Such a complete set of equipment configuration needs 23 million, but the entire production line only needs five or six workers to complete the production operation and realize automatic production.

Among them, the reasonable collocation of the fineness of raw materials is crucial for the production process of organic fertilizer. The fineness of the whole raw material should be matched as follows: 100-60 mesh raw material accounts for about 30-40%, 60-mesh raw material accounts for about 35%, and small particles with diameter of 1.00-2.00 mm account for about 25-30%. The higher the fineness of the material, the better the viscosity, and the higher the surface finish of the particles after granulation. However, in the production process, the use of super proportion and high fineness materials is easy to cause problems such as oversized particles and irregular particles due to poor viscosity.