Application effect of composter before processing fertilizer in organic fertilizer production line

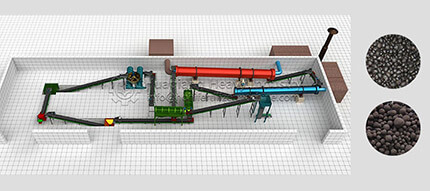

organic fertilizer production line

organic fertilizer granulator

How to realize the green reuse of the double roller granulator resources is a problem that everyone is concerned about. On the other hand, the double roller granulator is an innovative product designed and produced under such a big premise. Why do you say that? I will give you a detailed introduction:

First of all, the double roller granulator is widely used to granulate some waste materials, such as coal powder, carbon powder, coke powder, carbon black, mineral powder, dust removal ash, lime powder and other metal mineral powder, as well as industrial recycled dust materials, iron casting plant dust, lead, zinc, aluminum dust, converter dust, filter dust, grinding dust, etc.

It really realizes the recycling of resources and greatly protects the environment. In terms of environmental protection, the processing operation of this equipment adopts the non dry normal temperature process, which has high particle strength and is more obvious than other granulation methods, especially suitable for the occasions where the bulk specific gravity of products increases. More importantly, the mechanical transmission system of the double roller granulator is completely sealed in the machine body. As the powder materials complete the granulation process in the wet state, there is no discharge of the three wastes during the granulation of the roll to roll granulator and the subsequent process operation, which truly realizes green production. The double roller granulator has realized the green reuse of resources and has huge market potential.

The double roller granulator has the following advantages: 1. It operates circularly to realize continuous production and high output of finished products; 2. The material is forced to be compressed and shaped by mechanical pressure without any additives, so as to ensure the purity of the product. 3. The particle strength can be adjusted, and the finished product strength can be controlled by adjusting the pressure of the roller; 4. The extruding granulator is applicable to various raw materials, and the particle strength can be adjusted freely according to different materials. 5. Compact structure, convenient maintenance, simple operation, short process flow, low energy consumption, high efficiency and low failure rate.

Take chicken manure as an example, stack chicken manure in strips on the site, sprinkle special fermentation bacteria agent for organic fertilizer on the surface of raw materials, add dry materials/auxiliary materials in an appropriate amount according to the moisture content, and the general ratio of raw materials: auxiliary materials is 3:1, The width and height of the stack are determined according to the respective compost turner model.

The application scope of organic fertilizer granulator is: peat fermentation, sludge fermentation, cow, sheep, chicken, pig manure fermentation, straw fermentation, residue fermentation, residue fermentation for mushroom cultivation, domestic waste fermentation, etc. According to the microelements required by crops, organic fertilizer and bio organic fertilizer can be made from raw materials without damaging beneficial bacteria. It is a green organic fertilizer used for agriculture, forestry, flowers, trees and vegetable crops. It can handle garbage and increase environmental protection.

The oxygen consumption of compost is related to the content of organic matter in compost raw materials. The more organic carbon in compost materials, the greater the oxygen consumption. The suitable oxygen concentration of raw materials for chicken manure organic fertilizer production enterprises in the composting process is 18%. When the oxygen concentration is lower than 18%, the life activities of microorganisms in the good composting process are limited, which is easy to make the compost enter the anaerobic state and produce odor.

Many customers are concerned about whether the materials in the production of organic fertilizer will corrode the organic fertilizer peripheral equipment. If the material corrodes the machine, the service life of the turnover machine and equipment will be shortened, and the production cost of organic fertilizer will increase, which is not a cost-effective investment for enterprises.

However, the manufacturer of the organic fertilizer turnner clearly told everyone here that the production of organic fertilizer would not cause corrosion to the tipper. If it is not used for a long time, the equipment needs to be thoroughly cleaned, otherwise it will cause corrosion to the machine. This is because if the machine is not used for a long time, the residual substances in the machine will combine with the water molecules in the air to form a large amount of water, and the contact parts will be corroded after a long time of contact with the machine, but this will not happen in the normal production cycle.

Organic fertilizer granulator is a kind of equipment for producing organic fertilizer, which is widely used in organic fertilizer production. Most of it is used in good farmland, fruits, vegetables, etc., which is conducive to environmental protection. However, the noise of the organic fertilizer granulator is very loud in the work, which also affects the hearing of the operator and brings great trouble to people. Today, we shared the advantages of organic fertilizer granulator and the methods to control noise.

Advantages of organic fertilizer granulator

After adding the roller, the roller can be pressed for 2-3 times, extending the service life of the organic fertilizer granulator, reducing the production cost, and increasing the profit margin of the investment project.

The main results are as follows: (1) Bioorganic fertilizer granulation was carried out with peat, lignite, organic fertilizer sludge and straw as raw materials.

(2) Granulation of organic fertilizer with chicken manure and other organic fertilizers as main raw materials.

(3) Cake fertilizer mainly made of soybean cake.

(4) Full price feed and mixed feed with corn, beans and grass flour as raw materials.

(5) Granulation of bio feed straw with crop straw as raw material.

The main purposes of producing organic fertilizer from feces with a pair of double roller granulators can be summarized in four aspects:

1、 Stabilization: through centralized aerobic composting and large-scale treatment, the organic matter in the feces can be degraded to achieve the purpose of stabilization and avoid secondary environmental pollution caused by material mildew and odor.

2、 It is harmless. It kills parasite eggs and pathogenic microorganisms through disinfection to prevent infectious diseases from spreading on the land and promote food safety production.

3、 Utilize resources to realize the recycling of manure, turn harm into benefit, turn waste into treasure, and provide a large amount of high-quality fertilizer for the development of organic agriculture.

4、 Industrialization will establish a new economic growth point for pig farms. Through large-scale and mechanized production of organic fertilizer plants, manure composting will be further processed into powder or granular commercial organic fertilizer

This is why the double roller granulator not only saves energy and environmental protection, but also fully reflects the green nature of organic fertilizer. The efficiency of organic fertilizer is obvious.

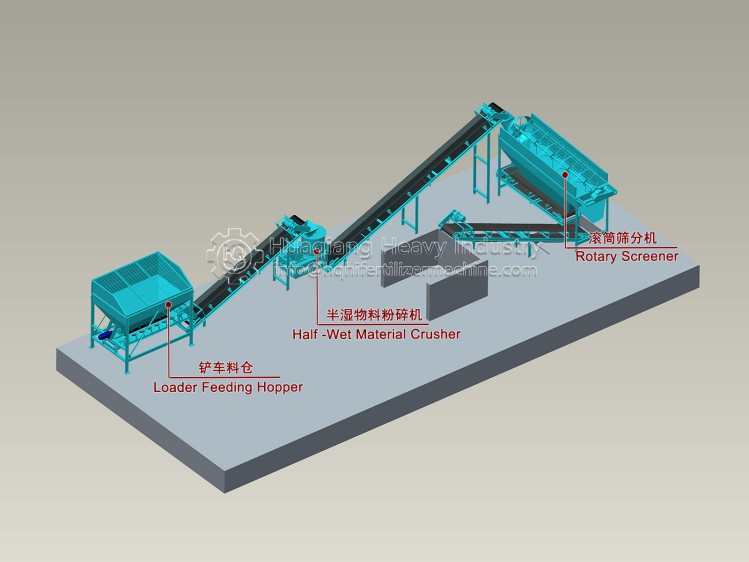

Fertilizer equipment drum screener machine is divided into ordinary screening machine, automatic beating device screening machine. According to the general screening equipment, we specially designed the drum screening machine, which has small screening resistance, small power and standard thickness steel plate. The designed dust cover can remove the powder dust, improve the working environment and protect the environment. This kind of fertilizer equipment after-sale maintenance is simple and convenient, only need to replace the screen.

More and more farmers are looking for ways to produce organic fertilizer as the organic movement continues to grow. While there are many commercial products available, some farmers are choosing to make their own fertilizer using organic production equipment.

There are a few things to keep in mind when using organic fertilizer production equipment. First, it is important to choose the right equipment for your needs. There are a variety of organic fertilizer production systems available, so it is important to select the one that best fits your operation.

Second, it is important to follow the manufacturer’s instructions when using the equipment. This will ensure that you are using the equipment properly and that you are getting the best results.

Finally, it is important to monitor the organic fertilizer production process carefully. This will help you troubleshoot any problems that may arise and make sure that the fertilizer is being produced correctly.

Bucket elevator is used as the conveying equipment of organic fertilizer production line and npk blended fertilizer. How to deal with failures in the application process?