Take chicken manure as an example, stack chicken manure in strips on the site, sprinkle special fermentation bacteria agent for organic fertilizer on the surface of raw materials, add dry materials/auxiliary materials in an appropriate amount according to the moisture content, and the general ratio of raw materials: auxiliary materials is 3:1, The width and height of the stack are determined according to the respective compost turner model.

Take the compost turning machine as an example, the compost body is 2 meters wide and 0.8 meters high, and the length depends on the length of the site. Then, the dumper straddles the top of the chicken manure pile to evenly turn, stir and crush the raw materials, so that the chicken manure, dry materials, auxiliary materials and bacteria can be fully stirred evenly. The dumper has the crushing function. Even if there are large pieces of chicken manure or dry materials, the large pieces can be opened and broken under the action of the turner.

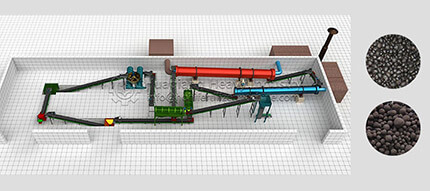

After the turning machine turns the stack, a new stack is formed, and the new stack is in a fluffy and loose state, creating a favorable aerobic state for the fermentation of materials, which is very conducive to the production and fermentation of organic fertilizer. In this state, the pile that has been turned over can rise to a high temperature within 24 hours, and the pile can be maintained at a high temperature for 2-3 days before turning over. This state has basically become fat in 7 days. Subsequent to stand staleness, the fertilizer granulator can be used to make high-quality fertilizer products.