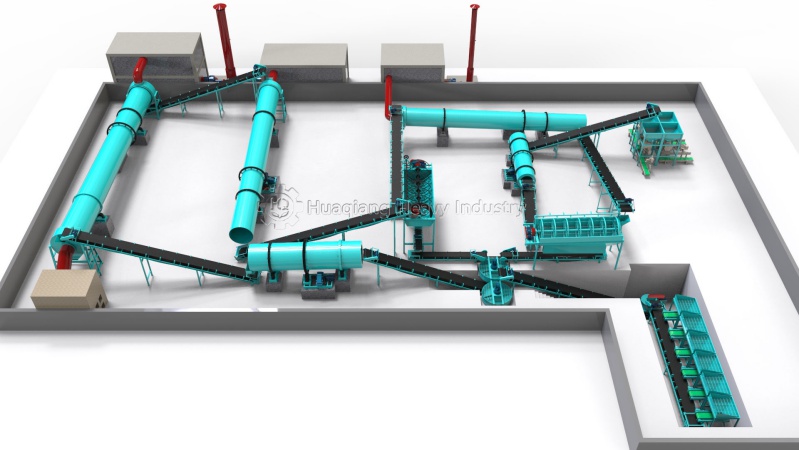

The application of rotary drum granulator in NPK (nitrogen phosphorus potassium) fertilizer production line has demonstrated many technological and economic advantages, making it an indispensable part of NPK fertilizer manufacturing. The following points elaborate on the main advantages of the rotary drum granulator:

1. Efficient granulation

Uniform particle size: The rotary drum granulator can generate very uniform particles, which helps improve the accuracy of fertilization, reduce waste, and also enhance the appearance quality of fertilizers

High strength granules: NPK fertilizer granules that have been granulated have high compressive strength, are not easily broken, are easy to transport and store over long distances, and reduce losses.

2. Large scale production capacity

Continuous production: The rotary drum granulator can achieve continuous and large-scale production mode, which is very suitable for the needs of modern large-scale fertilizer factories and effectively improves production efficiency.

Scalability: The drum size and configuration can be adjusted according to production needs, making it easy to cope with upgrades or expansions of production lines of different scales.

3. Easy to control and adjust

Parameter adjustment: The speed, tilt angle, filling rate and other parameters of the drum can be finely adjusted to adapt to different raw material characteristics and target particle specifications, ensuring high-quality granulation effect.

Automated operation: Most rotary drum granulators are equipped with advanced automation control systems, which simplify the operation process, reduce labor costs, and ensure production consistency and reliability.

4. Cost effectiveness

Low energy consumption: Compared to some other granulation methods, the rotary drum granulator consumes less energy during operation, which helps to save operating costs.

High utilization rate of raw materials: The fine powder generated during the granulation process can be recycled into the granulation cycle through the recycling system, reducing the waste of raw materials and improving economic benefits.

5. Environmentally friendly

Dust control: The enclosed granulation environment reduces dust flying, protects the working environment, and is beneficial to employee health and the surrounding ecology.

Wastewater treatment: The wastewater generated during the granulation process can be recycled and reused, reducing water resource consumption and minimizing environmental impact.

In summary, the rotary drum granulator has brought an efficient, reliable, and economical granulation solution to the NPK fertilizer production line, which not only improves the quality of fertilizer products but also promotes the sustainable development of the entire industry. Against the backdrop of increasing emphasis on environmental protection and efficient resource utilization, the application prospects of rotary drum granulators are very broad.