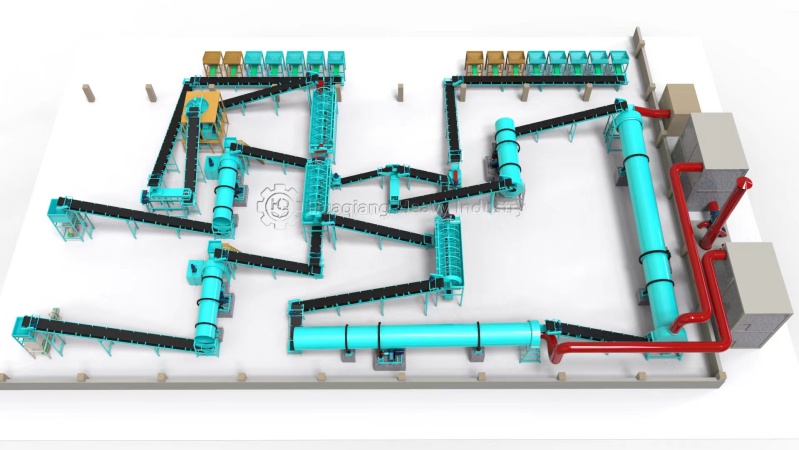

The sheep manure processing organic fertilizer production line is an industrial process that converts sheep manure into organic fertilizer. It involves multiple steps to ensure that the final product is both safe and efficient. The following is a typical process flow of an organic fertilizer production line for sheep manure processing:.jpg)

1. Raw material collection and storage

Collect fresh sheep manure and transport it to the storage area.

2. Preprocessing

Crushing: Preliminary crushing of sheep manure to reduce its particle size for subsequent fermentation and mixing.

Remove impurities: Remove large impurities such as stones and plastics from sheep manure by screening.

3. Mixing

Mix the crushed sheep manure with other auxiliary materials (such as straw, sawdust, etc.) in a certain proportion to regulate the carbon nitrogen ratio and water content, and promote microbial activity.

4. Fermentation

Stacking the mixed materials in piles and accelerating the fermentation process through natural fermentation or adding microbial agents can kill pathogens and weed seeds while generating heat, which helps stabilize the nutritional content of the fertilizer.

5. Overturning

Use a compost turner to regularly flip the fermentation pile to ensure even fermentation and improve fermentation efficiency.

6. Dehydration

The material after fermentation has a high moisture content and requires the use of a dehydrator for dehydration treatment, in order to facilitate subsequent granulation and packaging.

7. Granulation

The dehydrated material is processed into granules using an organic fertilizer granulator, and the granular fertilizer is easy to apply and store.

8. Drying and cooling

The organic fertilizer after granulation contains a certain amount of water and needs to be dried by a dryer. Then, the temperature of the fertilizer is lowered by a cooling machine for easy packaging and storage.

9. Screening

Use a screening machine to screen the dried and cooled granular fertilizer and remove particles that do not meet the specifications.

10. Packaging

Quantitatively package the screened granular fertilizer for transportation and sales.

11. Quality inspection

Throughout the entire production process, it is necessary to conduct regular quality inspections on the products to ensure that they meet the standards for organic fertilizers.

12. Storage and Transportation

Store packaged organic fertilizers in a dry and ventilated warehouse, ready for transportation to the market or farm.

The process flow of sheep manure processing organic fertilizer production line needs to be precisely controlled to ensure the quality of the final product. Through this process, not only can sheep manure resources be effectively utilized, but also high-quality organic fertilizers can be provided for agricultural production, promoting sustainable development of agriculture.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)