Many of the resources of the waste generated by residents’ life every day can be used and become organic fertilizer raw materials after secondary processing. The market position and bright development prospect of organic fertilizer production line are foreseeable. Automatic organic fertilizer equipment can work completely on its own without assistance, and has a high accuracy, avoiding the waste of resources, improving the qualified rate of goods, and saving many unnecessary economic expenses for enterprises. It can not only save costs for enterprises, but also create greater economic benefits for enterprises, higher production, so that goods can enter the market at the fastest speed and in the best period, and obtain the highest market sales.

Diversified organic fertilizer production lines in the limited market, it is inevitable to give something, some technology is backward, smaller manufacturers will kick out of the market, forced to close down. Therefore, in order to always have a larger application group, it is necessary to do a good job of communication with customers, do a good job of market research, and ultimately make the organic fertilizer production line better meet the needs of the public. Organic fertilizer is the same, in the past farmers are their own accumulation of organic fertilizer directly used, and now the improvement of living standards, high-tech organic fertilizer production lines are also used in the large-scale production of organic fertilizer. Organic fertilizer equipment makes life and production more convenient. Their use is different, organic fertilizer production lines to pursue the highest technology, so that it is more reused by the market, never out of date.

The organic fertilizer produced by the livestock manure organic fertilizer production line has complete nutritional elements, which can improve soil and improve soil compaction caused by the use of fertilizers. Improve soil physical and chemical properties, enhance soil water retention, fertilizer retention, and fertilizer supply capabilities. The beneficial microorganisms in the organic fertilizer production equipment of livestock and poultry manure enter the soil and form a symbiotic and proliferative relationship with the microorganisms in the soil, inhibiting the growth of harmful bacteria and transforming them into beneficial bacteria. They interact and promote each other, playing a synergistic role in the population. During the growth and reproduction process, beneficial bacteria produce a large amount of metabolic products, promoting the decomposition and transformation of organic matter, and can directly or indirectly provide various nutrients and stimulating substances for crops, Promote and regulate crop growth.

Organic fertilizer production equipment meets the needs of green agricultural development

As a series of problems such as resources and environment challenge human survival and development, organic fertilizer has once again become a research hotspot, and people begin to understand organic fertilizer from a higher level. Organic fertilizer is one of the important fertilizer varieties, which will play an increasingly important role in the sustainable development of agriculture. Its industrialized and commercialized production is a good way to overcome many shortcomings of traditional organic fertilizer. The advantage of commercial organic fertilizer lies in that it can develop its strengths and circumvent its weaknesses, take advantages of its advantages and make up for its deficiencies, and has a good effect on increasing production and income. It is deeply welcomed by farmers. Moreover, it is rich in raw materials, and the scientific and technological content of products is constantly improving. It is more and more welcomed by farmers in agricultural production, and plays a great role in the production and application of organic food.

In order to comply with the requirements of “accelerating the construction of resource-saving and environment-friendly society” in China, organic fertilizer equipment manufacturers combine agricultural production requirements and agricultural production environment to produce and manufacture efficient and energy-saving organic fertilizer production equipment, which can well ensure the production safety of organic fertilizer and protect the ecological environment. The production of organic fertilizer in China has begun to take shape, the market of organic fertilizer production line awareness is getting higher and higher, the sense of identity of organic fertilizer is also significantly improved, the development of organic fertilizer is urgent, the majority of farmers need to use organic fertilizer to enhance the market competitiveness of agricultural products, green and healthy agricultural products can bring more good benefits. Organic fertilizer production equipment is indispensable in the production of organic fertilizer, now the international attention to the production of organic fertilizer, the policy will also give preferential treatment, the market share of organic fertilizer continues to increase, but also shows that China’s development of green pollution-free agricultural products in the gradual realization of the plan, organic fertilizer production equipment in this link is indispensable.

Granulation process and equipment configuration of compound fertilizer production equipment

Compound fertilizer refers to a type of compound fertilizer that is made solely by chemical methods and contains at least two of the three nutrients: nitrogen, phosphorus, and potassium. Compound fertilizer has the advantages of high nutrient content, low side components, and good physical properties. It plays a very important role in balanced fertilization, improving fertilizer utilization efficiency, and promoting high and stable crop yields. But it also has some drawbacks, such as its nutrient ratio is always fixed, and the types, quantities, and proportions of nutrients required by different soils and crops are diverse.

The equipment configuration for compound fertilizer production varies according to the different raw materials, and suitable plans can also be made based on investment budgets. The prices of compound fertilizer production equipment vary with different yields. Firstly, it is important to consider the desired investment in the production of compound fertilizers, and then inform the manufacturer of the raw materials used for processing and production. This will provide an approximate price range for everyone, and then select the appropriate compound fertilizer production equipment configuration based on the expected investment.

The compound fertilizer production equipment is completed by closely combining multiple processes. Each process has strict indicator control, and none of them are indispensable. Firstly, technical personnel develop corresponding fertilizer production formulas based on market needs or customer demands combined with the market conditions of raw materials, and refine them into the amount of raw material input.

The process of compound fertilizer production equipment consists of multiple processes: raw material measurement, raw material crushing, granulation, drying, cooling, screening, coating, and packaging. The production line has always adhered to the principles of “fluidity, safety, operability, and aesthetics” in its design, achieving linear integration of mechanical and electrical systems throughout the entire production line, and will have considerable advancement for a considerable period of time in the future. Meanwhile, we can also adjust the process flow according to specific circumstances and requirements.

How to improve the revenue of farms and breeding farms with organic fertilizer granulators

After the painful suffering and trek of homogenization, the organic fertilizer granulator industry has ushered in a new era, that is, the era of differentiated competition. First, the standards of new fertilizers have been introduced, and the standards of slow and controlled release fertilizers are the most representative; Second, production enterprises and distributors have invested more energy in promoting organic fertilizer production lines, and the profits are relatively rich; Third, the negative confirmation, fake and shoddy products on the market perception is also quite keen, in the past year, in the name of a variety of new high-tech fertilizers to infringe on the interests of consumers occurred. Nowadays, the differentiated publicity is very loud: you say that your product is slow release, my product is controllable; You said your product had polypeptides in it, and mine had borzin; You said that your product is obviously drought-resistant, and mine can avoid deep ploughing; You said your products can strengthen seedlings, my products can promote roots; You say your product contains organic matter, and mine contains biological bacteria… When the dazzling array of fertilizer products with different functions continue to innovate, on the one hand, we are pleased to promote the industry of organic fertilizer equipment scientific and technological innovation, but also wondering whether the organic fertilizer granulator industry has entered a new cycle.

Working principle of pig manure organic compound fertilizer granulator:Various dry powder materials are added from the top of the equipment, subjected to degassing, spiral pre compression, and transported to the curved grooves of two rollers. The two rollers rotate at equal speed and in reverse direction, biting the materials into the grooves and forcing compression. The pressure the materials bear gradually decreases after passing through the compression zone, and their surface tension and gravity cause them to naturally come out. They enter the crusher and granulator for crushing and trimming, and then enter the vibrating screen for screening, Qualified products are sent to the finished product warehouse or directly packaged through a conveyor, and the powder screened materials are sent back to the raw material warehouse for secondary rolling through a feeding device. The size of the extrusion pressure can be adjusted by the hydraulic system according to the particle strength needs. By changing the groove form of the roller surface, materials such as flakes, strips, olives, and flat balls can be obtained.

Granulation process and equipment configuration of chicken manure organic fertilizer production line

A complete set of chicken manure organic fertilizer production equipment mainly consists of two parts: fermentation and granulation, and it is precisely because these two parts affect the overall price of the organic fertilizer production equipment sales industry.

For example, in small and micro chicken farms where the daily production of chicken manure is not large, as a responsible organic fertilizer production equipment sales enterprise, it is recommended that users only purchase the fermentation and composting machine separately. In this way, farmers only need to invest a small amount of funds to meet the needs of harmless treatment of chicken manure.

For slightly larger small and medium-sized chicken farms, experienced manufacturers and sales personnel usually propose customized organic fertilizer equipment for chicken manure organic fertilizer production equipment. This is because the specific configuration and cost of organic fertilizer production equipment for chicken manure are directly affected by factors such as different processing capacities, feeding methods, surrounding environments, and customer budgets.

The equipment configuration of the chicken manure organic fertilizer production line varies depending on the different raw materials, and suitable plans can also be made according to the investment budget. The equipment prices of the cow manure organic fertilizer production line vary with different yields. Firstly, it is necessary to consider the amount of organic fertilizer production that you want to invest in, and then inform the manufacturer of the raw materials used for processing and production. This will provide an approximate price range for everyone, and then select the appropriate production line configuration based on the expected investment. As mentioned earlier, the equipment of the chicken manure organic fertilizer production line is combined according to different production equipment and can be customized according to the production needs of users, with flexible investment adjustments.

Biological organic fertilizer production equipment can increase the revenue of aquaculture farms

The improvement of the quality of life, so that Huaqiang organic fertilizer production equipment has more pursuers, it is this way, organic fertilizer equipment deeply understand the importance of their own existence, deeply understand the importance of development. Deep technology, advanced science and technology have made biological organic fertilizer production equipment have more development opportunities, in the process of large market demand, organic fertilizer production line efforts are the requirements of The Times, but also the requirements of the market.

Organic fertilizer production equipment is initially a small part of the development of mechanization in China, and does not have much weight in the production of enterprises. It is a part of China’s organic fertilizer equipment and is not paid attention to. With the continuous expansion of the country, the domestic mechanization development is becoming more and more rapid. With the improvement of people’s living standards, there are new pursuits for the quality of organic fertilizer, and the figure of organic fertilizer production equipment has begun to appear in the market, and the scope of use has also begun to continue to be extensive. Bio-organic fertilizer production equipment according to the needs of the market continuous research and development and development, to create a variety of suitable for different types of organic fertilizer equipment to enhance the production of enterprises, for our lives to bring more convenience, now bio-organic fertilizer production equipment slowly become a necessity in life, And by the major enterprises and consumers love to our agriculture and breeding industry has brought great convenience and benefits..jpg)

Livestock manure organic fertilizer industry, like other fertilizer industries, has certain seasonality and regionality. The development of the industry is extremely dependent on the development level of agriculture and the overall economy. Areas with high economic development level pay more attention to food safety, and the demand for organic fertilizer increases year by year; In areas with developed agriculture, farmers are more clear about the benefits brought by the application of organic fertilizer, and are more willing to apply more environmentally friendly organic fertilizer, so as to achieve the purpose of land virtuous cycle and develop sustainable agriculture. In recent years, in order to meet the demand for high quality and high yield of crop planting, the application proportion and amount of organic fertilizer will be greatly increased.

Equipment and granulation process for organic fertilizer treatment of household waste

The organic fertilizer production equipment for household waste includes kitchen waste, fruit and vegetable waste, garden waste, leftover food and vegetables, and restaurant kitchen waste. The output can be used as raw materials for organic fertilizer. It is a new type of kitchen waste treatment equipment that swallows waste, spits out wealth, and turns waste into treasure. It saves time, effort, and labor, achieving fully automated operation.

The organic fertilizer production equipment for household waste is a mechanical equipment that provides necessary degradation and survival environment for microbial treatment bacteria of organic waste (such as kitchens, gardens, fruits and vegetables), and quickly degrades organic waste (such as kitchens, gardens, fruits and vegetables). This equipment provides suitable conditions such as temperature, humidity, and oxygen content for microbial treatment bacteria, enabling the rapid degradation of organic waste. Organic waste can be turned into feed, organic fertilizer, and reused with a moisture content of 12% powder particles..jpg)

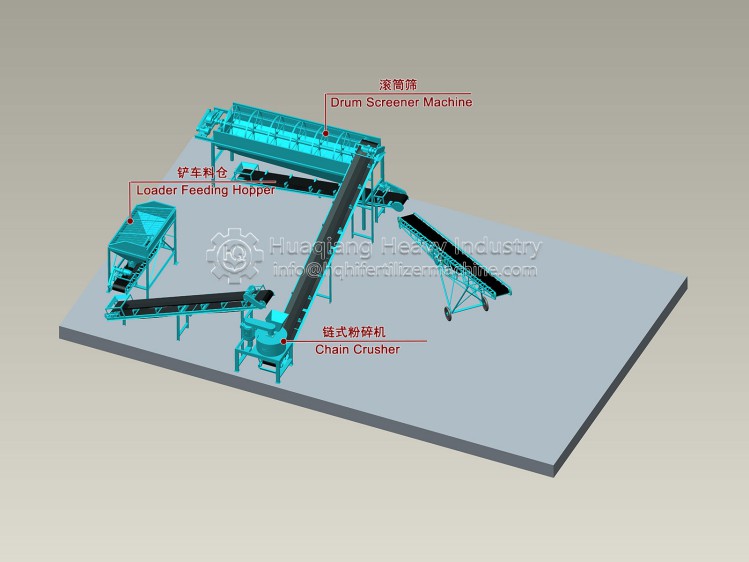

The process of organic fertilizer treatment equipment for household waste includes fermentation, crushing, stirring, granulation, drying, cooling, screening, film, packaging, etc. Fermentation is of the same size and requires tank type fermentation. According to the process, equipment such as fermentation flipper or stacker, material crusher, horizontal mixer (vertical mixer), organic fertilizer granulator (organic fertilizer combination granulator, disc granulator, etc.), organic fertilizer drum dryer, cooling machine, drum screening machine, coating machine, automatic weighing and packaging scale, conveyor, etc. are used in sequence.

Small and medium-sized organic fertilizer plants can use medium to low configuration organic fertilizer production lines for household waste organic fertilizer equipment, which can greatly reduce investment costs. The sales scope of finished organic fertilizer is limited to nearby areas, and some processes in the organic fertilizer production process require manual completion.

The process flow and advantages of small-scale organic fertilizer processing equipment

A set of small organic fertilizer equipment has different equipment configurations according to different raw materials, and suitable plans can also be made based on investment budgets. The price of a set of small organic fertilizer equipment with different yields also varies. Firstly, it is necessary to consider the amount of organic fertilizer production that you want to invest in, and then inform the manufacturer of the raw materials used for processing and production. This will provide an approximate price range for everyone, and then select the appropriate production line configuration based on the expected investment.

The process flow of organic fertilizer processing equipment is as follows: after the organic fertilizer raw materials are fermented, they are crushed in a semi wet material crusher, and then nitrogen, phosphorus, potassium and other elements are added to meet the required standards of mineral elements. Then, a mixer is used for stirring, and the particles enter the granulation mechanism. After coming out, they are dried and screened by a screening machine, and qualified products are packaged.

The so-called small-scale organic fertilizer equipment has a relatively small production capacity, a small equipment footprint, and a relatively low investment cost. A small-scale organic fertilizer equipment costs around 100000 yuan, and the operation is very simple. The requirements for the factory and equipment are low. Combined with the current ecological civilization strategy of the country, the market space and demand for organic fertilizer are very large. Investing in small-scale organic fertilizer equipment is a good choice.

A small-scale organic fertilizer production line can greatly save the cost of producing organic fertilizers and other products, improve production efficiency, and ensure good product quality and large batch production to meet the needs of a large number of users. In these areas, the development of organic fertilizer equipment plays a pivotal role. To develop agriculture well, protect the environment, and improve economic benefits, we need to put in a lot of effort in improving and updating organic fertilizer equipment, laying a solid foundation. Grasp every detail and do a good job in production development.

Organic fertilizer granulator should maintain innovative development and green environment

With the progress of science and technology, the market competition of organic fertilizer granulator is becoming more and more fierce, and how to grasp the market development quickly and effectively has become the key to the success of enterprises. In recent years, the scale and characteristics of the organic fertilizer pelleting equipment industry market have undergone great changes, how to understand the development of the organic fertilizer equipment industry and the transformation of the market from a professional perspective will become the primary issue for the future development and survival of enterprises. The quality of organic fertilizer granulator enterprises is seriously related to the interests of ordinary users, related to the overall development of the market economy, the equipment has more stringent requirements, in order to complete their own social mission, but also in order to better show their own value, the enterprise has been constantly growing, and constantly improve their own strength.

As an organic fertilizer pelleting machine enterprises should correct the development attitude is the key to success, but also to promote the industry gradually to a strong important driving force, in the future development, will always maintain a clear mind, not be captivated by the current achievements of the eyes, always maintain a positive learning attitude, for the powerful introduction of biological organic fertilizer production line more high-end technology, For the bright future of the industry, constantly reform and innovation around market demand. Although after a period of efforts, the overall technical level of the industry has been improved, and according to different market needs, various types of equipment have been developed, and the team has further expanded to provide more comprehensive and thoughtful services for market users. Users for organic fertilizer pelletizer demand will continue to change, so in order to stabilize their market position, to maintain a good state of development, enterprises continue to maintain the development attitude of scientific and technological innovation, the use of high-tech power to improve, so as to more meet the market development trend, more popular.

Organic fertilizer equipment is used to granulate various organic matter after fermentation, breaking through the conventional organic matter granulation process. Before granulation, the raw materials do not need to be dried or crushed, and spherical particles can be processed directly with ingredients, which can save a lot of energy. Traditional methods of fertilizing with nutrients such as manure and garbage not only cause certain harm to the environment, but also fail to fully utilize their effects. With the increasing use of organic fertilizers, compound fertilizers, microbial fertilizers, and fertilizers, more and more people are aware of the benefits of organic fertilizers on the soil. Organic fertilizers have gradually gained recognition from more people, and organic fertilizer equipment has gradually entered people’s daily life and production, Let more people know that organic fertilizer equipment is used for professional production of organic fertilizers.

The effect of dual axis crusher on the fermentation of organic fertilizer with biological feces

Poultry manure is a relatively high-quality organic fertilizer, which contains pure nitrogen, phosphorus (P2O5), and potassium (K2O) of about 1.63%, 1.54%, and 0.85%. Poultry manure must undergo sufficient decomposition before application, to inactivate parasites and their eggs, as well as infectious pathogens present in chicken manure, through the process of decomposition. Due to the high temperature generated during the maturation process of poultry manure, it is easy to cause nitrogen loss. Therefore, it is necessary to add an appropriate amount of water and 5% calcium superphosphate before maturation for better fertilizer efficiency. After being fully decomposed, poultry manure becomes a high-quality base fertilizer for crop cultivation, or is often used as a base fertilizer for year-round application in winter in fruit trees.

Organic fertilizer crushing equipment is a new type of high-efficiency single rotor reversible crusher designed for fermented poultry manure, urban sludge, pharmaceutical residue, alcohol residue, and water content between 20% and 40%. It has good crushing effect and does not require screening. It has strong adaptability to the moisture content of materials, especially for fermented decomposed garbage or other materials with a moisture content not exceeding 30%. The particle size of the powder can reach 20-30 mesh, which can meet the feed particle size requirements of general organic fertilizer, bio organic fertilizer, and powdered organic fertilizer granulation equipment. It is one of the ideal equipment for organic fertilizer equipment.

The dual axis crusher allows for a moisture content of 25-50% for biological fermentation organic fertilizer materials, with a crushing particle size of 20-30 mesh or more, meeting the standard for direct granulation. In addition, it can also be adjusted according to customer needs. This crusher also has a certain crushing effect on hard materials such as glass, ceramics, and bricks in urban household waste organic fertilizer, which can achieve safe production and application. In addition, this crusher has a very good crushing effect on fermented materials, chicken manure, cow manure, pig manure, sludge, humic acid, and other raw materials in composting production. This crusher provides customers with effective, economical, environmentally friendly, high-performance, high-yield, and high-quality equipment!