Choosing a suitable self-propelled organic fertilizer turning machine is crucial for agricultural production and organic fertilizer manufacturing enterprises, as it relates to production efficiency, product quality, and the economic benefits of the enterprise. Here are some key purchasing points.

Firstly, clarify your own needs. The model and specifications of the organic fertilizer turning machine should be determined based on the production scale. If it is a small farm or breeding farm, the daily amount of organic materials that need to be processed is relatively small, and a small and lightweight self-propelled organic fertilizer turning machine can be chosen. This type of equipment has relatively low prices, small footprint, flexible operation, and can meet the needs of small-scale production. For large organic fertilizer production enterprises with large processing capacity and open space, it is necessary to choose a large and powerful self-propelled organic fertilizer turning machine to ensure efficient and stable production.

Secondly, consider the work environment. The conditions of different work sites vary greatly, such as terrain, ground smoothness, etc. If the terrain of the site is complex, with slopes or potholes, a tracked self-propelled organic fertilizer turning machine should be selected, which has good passability and can adapt to various harsh terrains. If the site is relatively flat and open, a wheeled self-propelled organic fertilizer turning machine may be more suitable, as it has a fast driving speed and high operating efficiency.

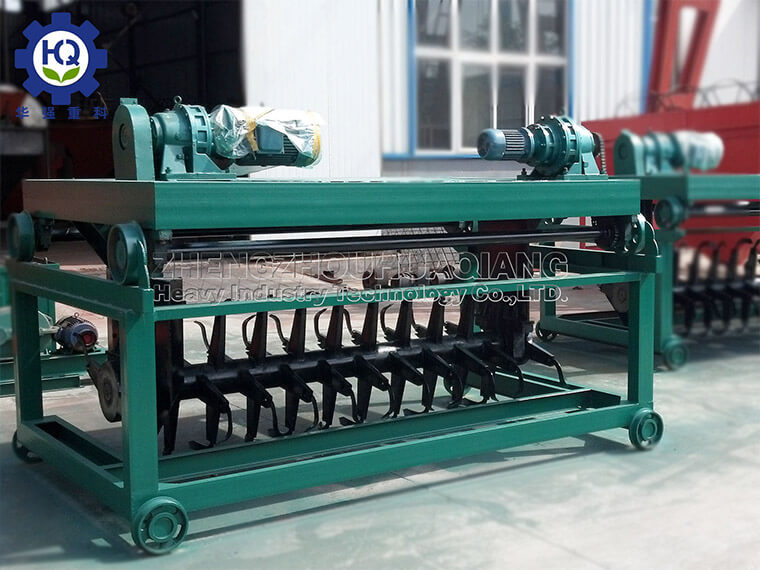

Equipment quality is key. High quality self-propelled organic fertilizer turners typically use high-strength steel to manufacture the chassis and key components, ensuring the equipment is sturdy and durable. Check the welding process of the equipment, the welds should be uniform, firm, and free of defects such as cracks. At the same time, attention should be paid to the quality of the flipping components, such as the wear resistance and strength of the flipping rake teeth, which directly affect the flipping effect and the service life of the equipment.

The convenience and automation level of operation cannot be ignored. Advanced self-propelled organic fertilizer turners should have a user-friendly interface that is easy to operate. Highly automated equipment can automatically adjust the flipping speed, depth, etc. according to preset parameters, reducing manual intervention and improving production efficiency and quality stability.

In addition, the after-sales service of the equipment should be examined. Choose a supplier with good after-sales service to ensure timely repair and technical support in case of equipment failure. Understand the supplier’s accessory supply situation, ensure timely supply of accessories, and reduce equipment downtime.

Price is one of the factors to consider when making a purchase, but it cannot be determined solely by the price. On the premise of ensuring that the equipment quality, performance, and after-sales service meet production needs, multiple comparisons should be made to choose products with high cost-effectiveness.

In short, when choosing a suitable self-propelled organic fertilizer turning machine, it is necessary to consider multiple aspects and make cautious decisions, in order to select the most suitable equipment for agricultural production and organic fertilizer manufacturing, and provide strong support for the development of enterprises.

.jpg)

.jpg)

.jpg)