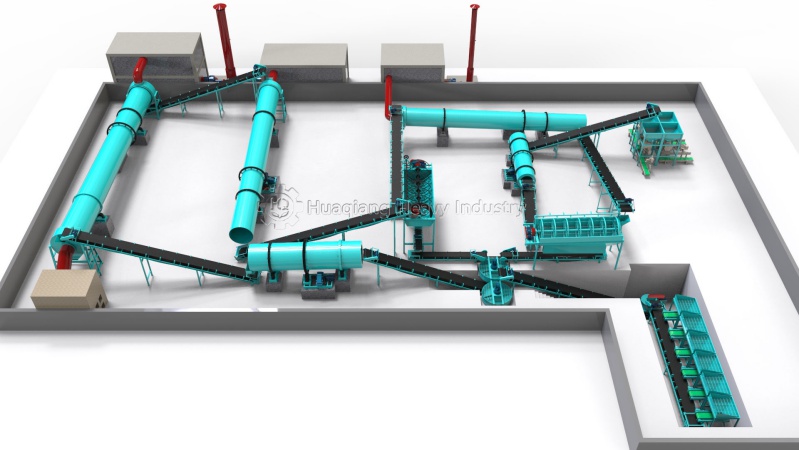

The equipment configuration of the poultry manure organic fertilizer production line is designed based on the characteristics of poultry manure, production scale, fertilizer quality requirements, and cost-effectiveness. A complete poultry manure organic fertilizer production line usually includes the following key equipment and process flow:

1. Raw material pretreatment equipment

Solid liquid separator: used for preliminary dehydration of poultry manure, removing excess water and improving the efficiency of subsequent processing.

Crusher: Grind the separated solid and liquid poultry manure to achieve uniform particle size, facilitating mixing and fermentation.

Blender: Mix crushed poultry manure with auxiliary materials (such as straw, sawdust, grass powder, etc.) and microbial agents evenly to promote fermentation and improve fertilizer quality.

2. Fermentation equipment

Fermentation tank or fermentation chamber: used for composting fermentation, which decomposes organic matter in poultry manure through microbial activity, generating high temperatures to kill bacteria and eliminate pathogens.

Stacker: Regularly flips materials during the fermentation process to ensure oxygen supply and uniform fermentation.

3. Drying equipment

Drying machine: The fermented material needs to be dried to remove excess moisture for granulation and storage. Common drying machines include drum drying machines, belt drying machines, etc.

4. Granulation equipment

Granulator: Choose the appropriate organic fertilizer granulator according to the needs, such as disc granulator, roller extrusion granulator, drum granulator, etc., to process the dried material into granules.

Screening machine: used to screen particles after granulation, remove unqualified particles, and ensure uniform particle size of the product.

5. Post processing equipment

Cooling machine: cools the granules after granulation to avoid the impact of high temperature on packaging and storage.

Packaging machine: Quantitatively package cooled granular fertilizers for easy sales and transportation.

6. Auxiliary equipment

Conveyor: Used for transporting materials between different equipment to improve production efficiency.

Dust removal system: reduces dust emissions during the production process and improves the working environment.

Control system: including PLC control system, used to monitor and adjust the operating parameters of the production line, achieving automated production.

7. Exhaust gas treatment equipment

Deodorization device: used to treat the foul odors generated during the fermentation process, ensuring the environmental friendliness of the production line.

The selection and configuration of equipment need to comprehensively consider factors such as production scale, raw material characteristics, target product quality, and budget. Reasonable equipment configuration and process design are key to ensuring the efficient operation of the poultry manure organic fertilizer production line and the production of high-quality fertilizers.