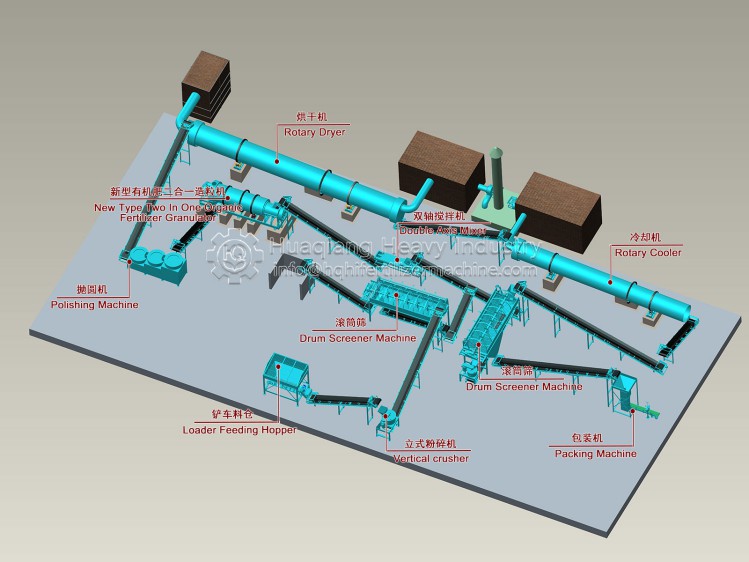

The fertilizer production line is to be designed and used to produce the npk compound fertilizer and organic fertilizer.So how many process is to be designed by the fertilizer machine manufacturers?The npk fertilizer production line is to be designed for producing the npk fertilizer,so there we share the npk fertilizer manufacturing process in this article.

1.Compounding process:The operator shall add various raw materials such as N,P,K and additives to the elettronic belt weigher in strict accordance with the requirement of the technician of each kind of raw material addition amount.The addition process of raw materials requires that the raw materials shall be powder or granular without caking,and the materials flow shall be uniform,and the operation shall not be interrupted from time to time.

2.Comminution process of compound fertizer:Accprding to the design requirements,the mixed fertilizer is transported to the raw material crusher for raw material crushing,the purpose is to crush all kinds of raw materials to a certain fineness,basically making the particle size of raw materials less than 1mm,which is conducive to the rolling of materials into standard balls in the granulator.

3.Granulation process of compound fertilizer:In the npk fertilizer production line,it is to be equipped with different type and series fertilizer machine to finish different production process.The crushed raw materials enter the conveyor of the belt conveyor and are transported to the fertilizer granulator machine of the rotary drum granulator for granulation.The solid fertilizer powder that needs to be granulated rises with the help of the rotation of the cylinder,and rolls down under the action of gravity.At the same time,granulate according to the amount of raw materials and the proportion of binder.The materials are wrapped on the surface of nucleation layer by layer,and thicken layer by layer.

Gradually granulating,under the action of the above forces,the material gradually forms the base core until it reaches the granulation requirements and enters the drying section.

4.Drying process of compound fertilizer:The dryer adopts the method of cylinder edge transmission,flange connection and direct heat transfer,which is suitable for the drying of compound fertilizer after granulation.The materials to be dried enter the drying area of the board with special combination.Due to the tilting movement of the body and the board,the materials are continuously taken up by the board to be fully scattered and moved longitudinally.

At the same time,it can fully exchange heat with the high temperature furnace gas from the hot blast furnace,evaporate water and dry the materials.Materials and flue gas need to be dried and operated in a downstream and micro negative pressure way.

5.Cooling process of compound fertilizer:The rotary cooler is mainly used for the cooling of compound fertilizer products after drying.It can directly cool the hot granular material fertilizer to near normal temperature.The material entering the cooler moves forward continuously under the rotating and tilting action of the body.At the same time,the induced draft fan from the tail of the cooler to the head meets the material countercurrent,taking away the heat of the material.

In the process of cooling,the cold wind also takes part of the water.

The cooled materials are easy to be packed in time and quickly to prevent caking during storgae.The machine adopts micro negative pressure operation,which reduces pollution and improves working environment.It has the characteristics of reasonable structure,stable operation and strong adaptability.The cooled materials are transported to the sixth sectionn by belt conveyor.

6.Screening and large particle crushing process of compound fertilizer:Screening section is mainly to separate fine powder,finished product and large particle materials.First,the fine powder in the semi-finished produce is separated,and then the large particles are separated.

The separated large particles are crushed by the large particle curhser,and then enter the return belt together with the separated fine powder,and return the granulator for granulation.Finished products enter the seventh section.

7.Packaging process of compound fertilizer:The finished products is lifted to the bin on the packaging machine by the leather elevator,unloaded to the weighing scale body and carried out the automatic weighing peration according to the set weigning weight.The weighed material enters the sewing bag section through the conveyor,and then the sewing bag operation is carried out and put into the finished product warehouse.

Besides the npk fertilizer production line is to be designed for producing the npk,compound fertilizer,the organic fertilizer production line is also to be designed for producing the organic fertilizer.In the fertilizer manufacturing process,when producing the organic fertilizer by using the complete fertilizer production line and fertilizer machine to finish the production process,it improves the working efficient,at the same time,it also saves more labor cost.