Organic fertilizer is a fertilizer made from organic waste such as animal manure, which is safe and environmentally friendly. It can not only increase crop yield but also improve soil quality. The supporting equipment for the production of organic fertilizer from livestock and poultry manure is as follows: fermentation tank, organic fertilizer flipping machine, crusher, screening machine, granulator, round throwing machine, packaging scale, and other organic fertilizer production lines.

Horizontal fermentation tank

Animal manure and auxiliary materials enter the fermentation tank and are quickly deodorized within 2-3 hours under the action of aerobic bacteria. By evenly supplying oxygen to the fermentation tank through the air supply and aeration system, the oxygen demand during the fermentation process is met, allowing the material to fully ferment and decompose. The high-temperature stage is maintained for 4-5 hours. The increase in temperature and ventilation and oxygenation accelerate the evaporation of moisture in materials. The waste gas and water vapor are treated and discharged through the deodorization system, thereby reducing the volume of materials and achieving the goal of reducing, stabilizing, and harmless treatment of materials.

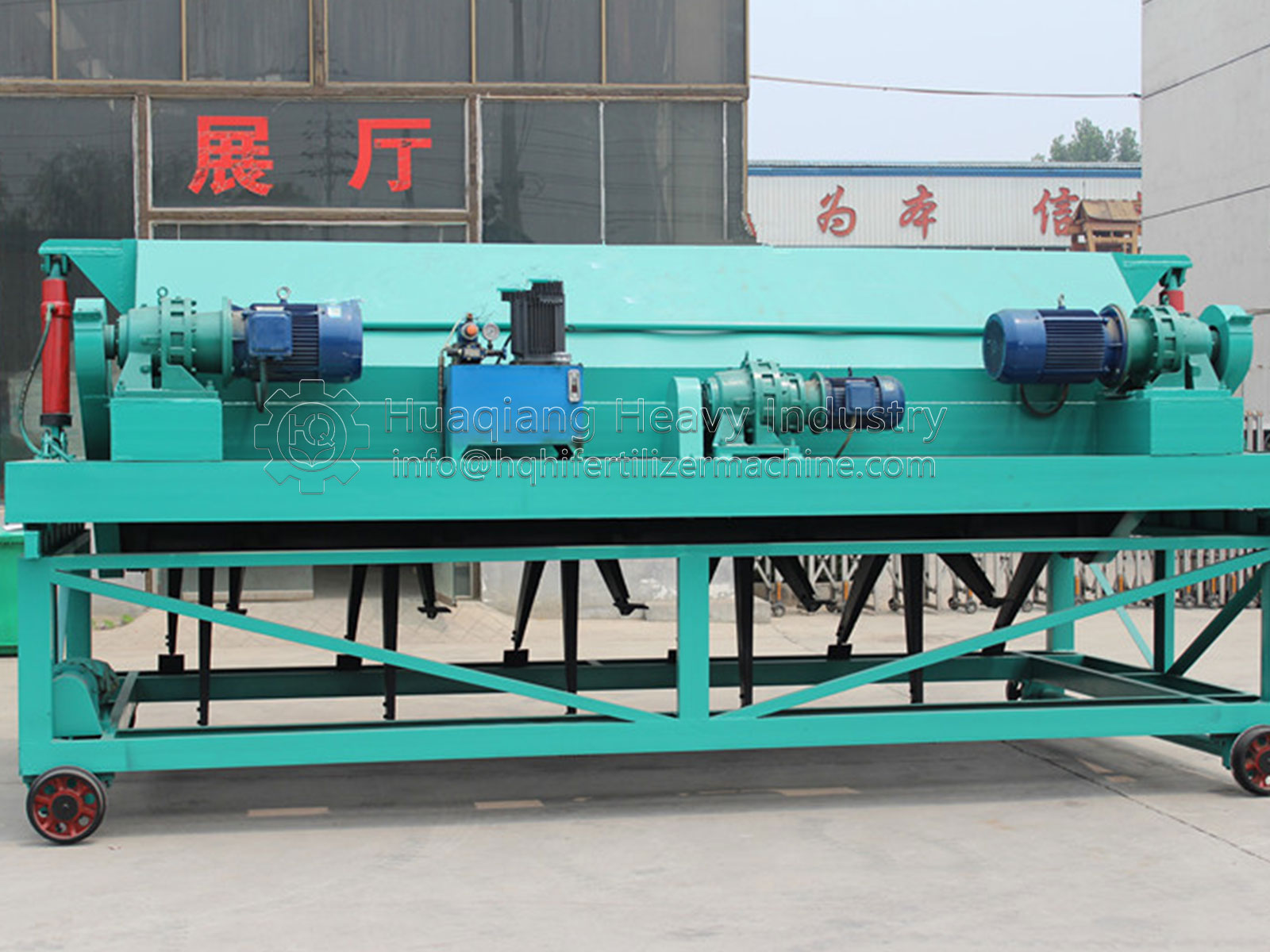

Organic fertilizer hydraulic lifting and flipping machine

Mix livestock and poultry manure, straw, bacterial residue, fermentation strains, etc. to a moisture content of 60-65% and send them to the fermentation tank through an automatic distribution system. Then, the freely walking track type flipping machine on the fermentation tank will perform flipping, stirring, and material transfer work. Adopting a continuous production process, which requires regular flipping, feeding, and discharging every day to ensure continuous production and low production costs for fertilizers.

Organic fertilizer packaging and granulation equipment

The organic fertilizer processing workshop is equipped with a production, processing, and packaging line for powdered and granular (biological) organic fertilizers, including a forklift feeding hopper, crushing, screening, batching, mixing, granulation, drying, cooling, screening, coating, packaging, etc. It can flexibly add or reduce a certain process according to actual production needs.

The high-temperature aerobic fermentation treatment process is to mix organic waste and auxiliary materials (crushed sawdust, rice husks, corn stover, corn cob, peanut shells, etc.) in a certain proportion, and make fermentation strips with fermentation conditions. Under the action of aerobic fermentation bacteria, the organic matter continuously decomposes, producing a large amount of high temperature, promoting the evaporation of water in the materials, and killing pathogens, parasites, and weed seeds under high temperature conditions, achieving the goal of harmless treatment; The fermented materials can be used as raw materials for organic fertilizers and landscaping, achieving resource utilization.